Industry 4.0 revolutionizes the manufacturing process, where smart systems and modern technologies are key drivers of innovation.

At the center of the energy transformation, control electrical cabinets become an indispensable element. Playing a crucial role in creating energy-efficient production. Through advanced design and manufacturing, control electrical cabinets contribute to the efficiency of manufacturing systems by setting new energy standards.

In the article, we explore the changes arising from the adoption of technology brought by Industry 4.0. Also, the important role of control electrical cabinets in the modern energy industry.

The role of control electrical cabinets

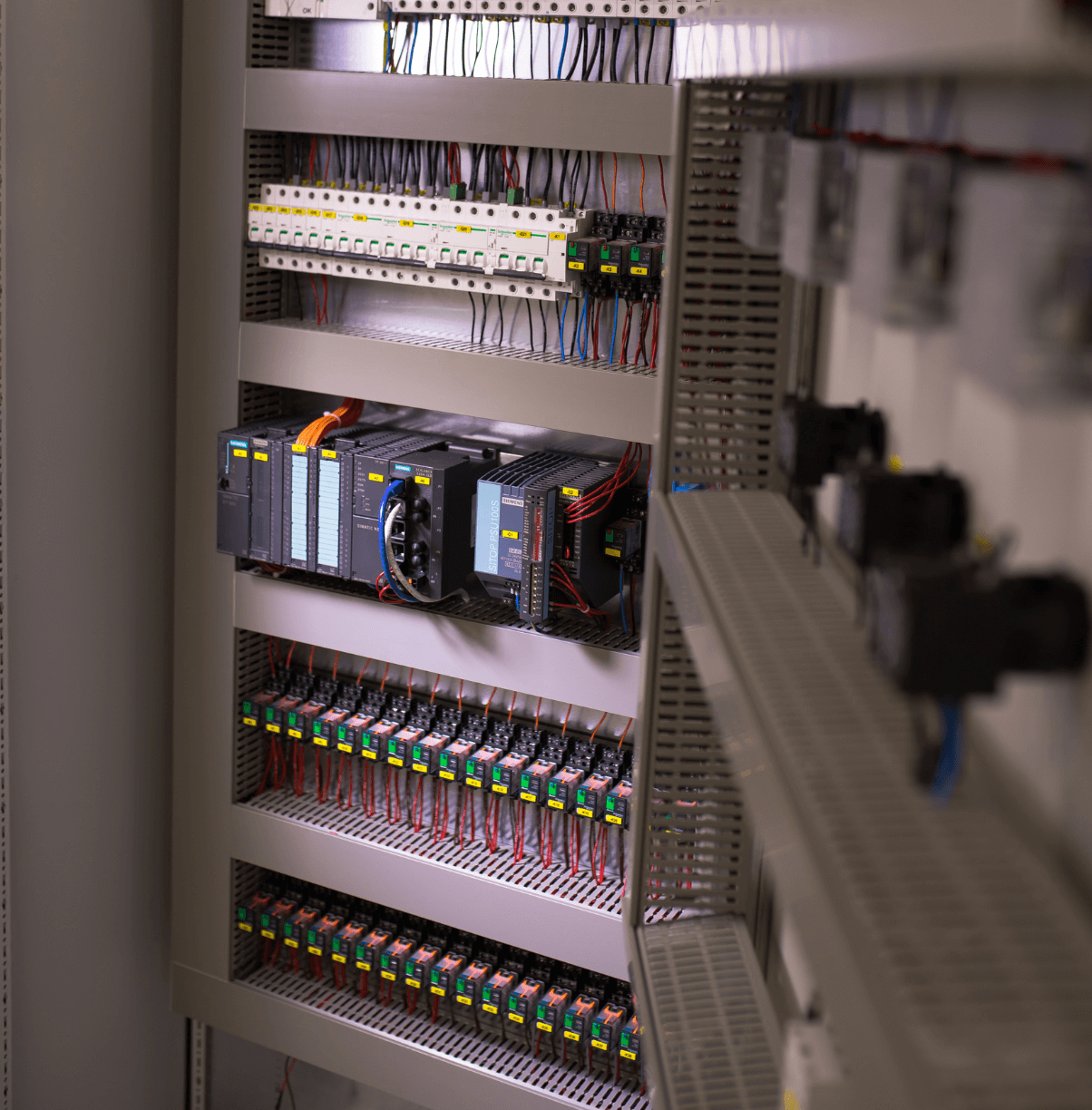

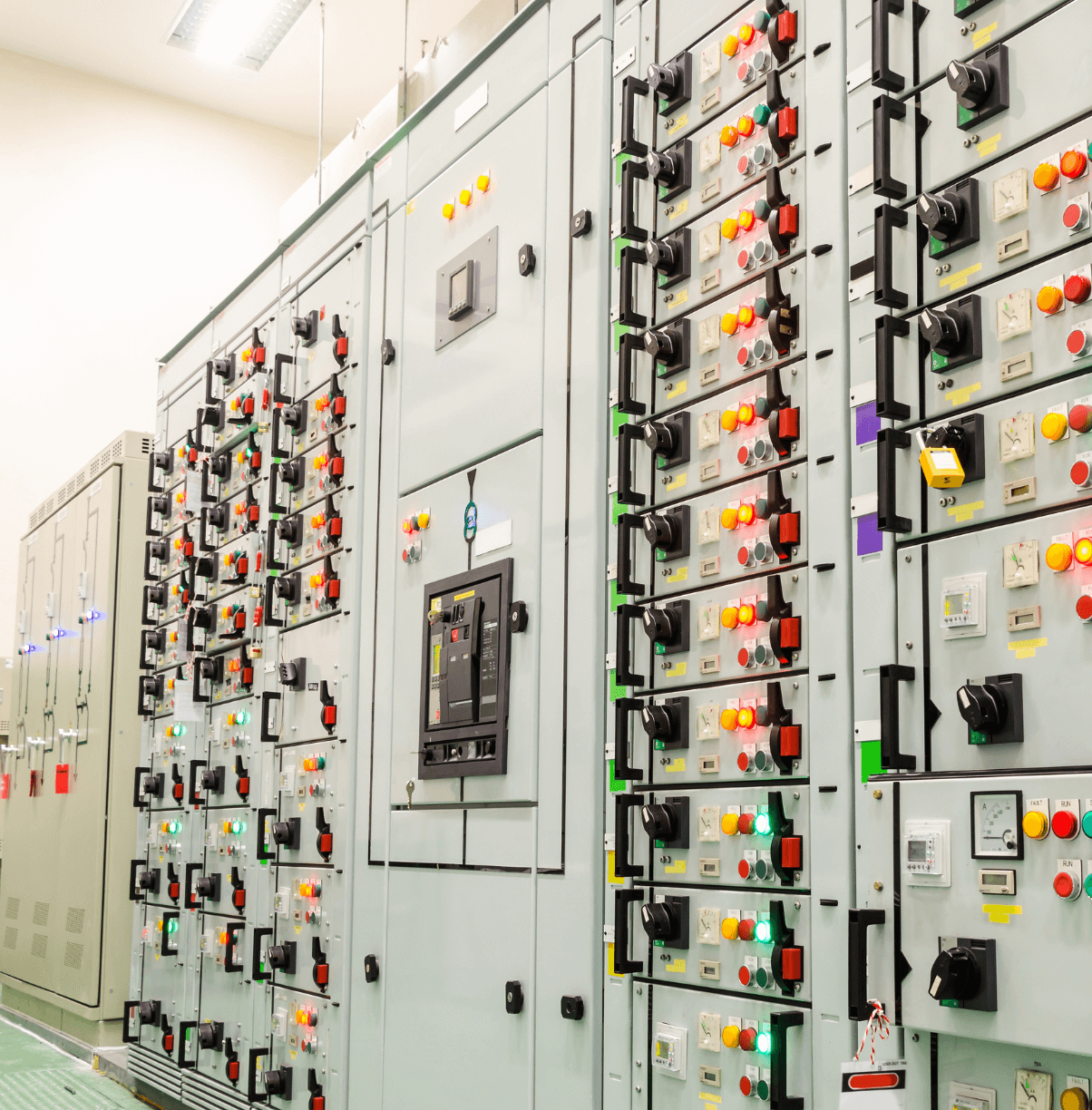

The role of control electrical cabinets in industrial plants is to ensure the stable and safe operation of electrical systems. Control electrical cabinets are an integral part of automated systems. Providing crucial support for the efficiency of the entire production process.

The basic function of control electrical cabinets lies in supervising and managing equipment, facilities, and related components. Furthermore, they enable precise monitoring of equipment performance, identification of potential issues, and quick response to problems that may arise during system operation. Furthermore, they allow for a quick overview and signaling of all errors and alarms on individual equipment.

They establish continuous monitoring of processes with trends and charts. Making it possible to predict and correct errors that may occur in the process.

Additionally, control cabinets often integrate advanced technologies, further enhancing monitoring and management capabilities. Innovative technological solutions enable process automation and minimize the risk of malfunctions and downtime.

By adopting accepted protocols (BACnet, Modbus, Mbus, etc.), it is possible to integrate different types of technology to obtain accurate information about the system, and increase the scope of equipment monitoring.

Control electrical cabinets become the foundation for modern industrial automation. Their role in ensuring the reliability and efficiency of electrical systems makes them an indispensable part of industrial plants in the contemporary environment.

Precision design as a step toward efficient automation

Advanced software tools like EPLAN are used for designing electrical cabinets, allowing engineers to precisely plan and document the project. EPLAN, as a sophisticated tool, facilitates the integration of different components. Optimizes equipment layout, and contributes to more efficient space management within the cabinet.

After creating detailed diagrams in EPLAN and the necessary information for routing and sizing cabinet components, they are transferred to the cloud and sent to the production facility where machines for manufacturing electrical cabinets are located.

Digitization speeds up the entire process of making electrical cabinets, from the initial design to assembling the cabinets as the final step. What sets high-quality control electrical cabinet apart is that modern ones are designed with one primary goal: achieving a higher level of energy efficiency. With a precise software model of the electrical cabinet, it is possible to determine wire length, color, and markings, achieving efficiency and reducing the cost of excess materials.

The modern production of control electrical cabinets not only ensures the optimal functioning of electrical systems but also follows modern trends in engineering.

Integration of advanced technologies and a focus on energy efficiency make them key components of modern industrial plants.

Control electrical cabinets and 3D design

To shorten the production process, a 3D handheld scanner is used, significantly improving scanning accuracy, which is then input into SolidWorks. Tools like SolidWorks are used to create 3D models of specific components or parts of electrical cabinets.

The advantage of 3D modeling is that it brings a high level of precision to the design of control cabinets. Engineers can model each component in detail, ensuring a perfect fit and optimal arrangement within the electrical cabinet.

3D modeling is a necessity because it significantly reduces common errors in the production of electrical cabinets. Another advantage is that it allows visualization that can be used to predict potential problems in the manufacturing process.

The primary role of using augmented reality (AR) technologies is positioning electrical cabinets and other components in the field to predict issues, and potential failures during installation.

Advanced methodologies for designing and manufacturing electrical cabinets not only improve precision and efficiency, but also enable manufacturers to create advanced and efficient control cabinets. As technology continues to advance, the adoption of digitization and modern design is a strategic imperative for companies dedicated to staying at the forefront of smart manufacturing.

Duplico OEM Electrical Cabinets

Our services include designing and assembling complex control and distribution electrical cabinets for various industrial applications. They are customized to meet your specific requirements.

Our specialty is creating customized or pre-designed control panels for OEM electrical cabinets. Services include equipment procurement, production of distribution panels, documentation, testing, and commissioning. We produce CE-certified electrical cabinets for the European market, and UL certification for manufacturing electrical cabinets for USA.

We have automated the process of manufacturing electrical cabinets. Furthermore, we use our software solutions to optimize the production processes for high-quality electrical cabinets.

Contact us for complex control system needs and assembly of one-time, small, and medium-sized batches of electrical cabinets.