Worlds #1 Energy source

Considering daily and yearly consumption volumes, oil is still second to none as a world-leading energy source.

In 2021 89,9 million barrels of oil were produced daily. The USA alone daily production equaled about 18.6 million barrels.

Despite the fast-paced oil production, the reserves are running low and, according to the latest reports will be sufficient for the following 47 years.

Oil producers are continuously seeking and investing in new sources and solutions aimed toward the renewal of production capabilities that ensure the maximum energy supply possible.

Oil Extraction

Despite the popular belief of numerous underground oil fields available 10 km underground and that by drilling holes, one would dip in the pool of oil and the extraction can start - the process of oil extraction is much more complex.

Oil can usually be found underground in hollow soil at pore levels and is raised to the ground and collected (alongside other materials like water and gas) into collecting stations through pipes where it is subsequently processed and sent to refineries.

Beam Pump or so-called Pumpjack

One of the most popular ways of oil production/extraction is production from the ground with so-called pumpjack machines. The “horse head” look-a-like machine that you can see on almost all oil fields.

Even though this is the most common way used for oil extraction, it is not without challenges and obstacles. If a pumpjack is not set up and managed properly, its work can be entirely counter-productive.

In cases of wells not so rich in oils, a continuous inflow of the oil and a synced operation of a pumpjack are crucial and the synchronization part is hard to be obtained.

Most of the pumpjacks functioning to the day are old, not automated machines that are not upgraded with new technologies. In rich wells, they are working 24/7 with occasional pauses.

In case when the well is not as rich in oil, the pumpjack is set to work at a particular time for a certain period. In cases when there is no oil in the well, the pumpjack will work nevertheless - risking the inflow of sand, dirt, or any other material with the potential to cause extensive damage leading to an expensive rehaul. The rehaul requires the pumpjack to be out of order for some time, again causing additional financial loss.

This instance particularly occurs in wells that are not equipped with sensors and monitoring or advanced status reporting. The pumpjacks are working with no clear data from the well in defined time terms, which leads to sand appearance, the collapse of the string, frequent overhauls, or pump destruction.

Sucker Rod Pump Automation

The most common solution to this problem is technologically advanced, sensor-rich systems that enable the synchronization of a pumpjack unit with an oil flow by helping to determine the precise speed for the pumpjack to run. Thus, oil extraction becomes fully automated.

Automation cuts maintenance costs improve production and enable proper management and monitoring. Automation also decreases the overhaul periods as the production improved while combined with sensors and deep hole diagram reporting.

Oil well automatization enables continuous production by regulating the work pace and a proper mechanical shutdown in cases of downhole wells not being eligible for production.

Duplico provides advanced technological solutions for oil well automatization, partnering with two most popular and renowned companies - UNICO and Lufkin.

As a certified partner, we have knowledge, expertise, and experience in good automation utilizing both Lufkins and UNICO product suites.

LRP Units - A great alternative to Pumpjack units

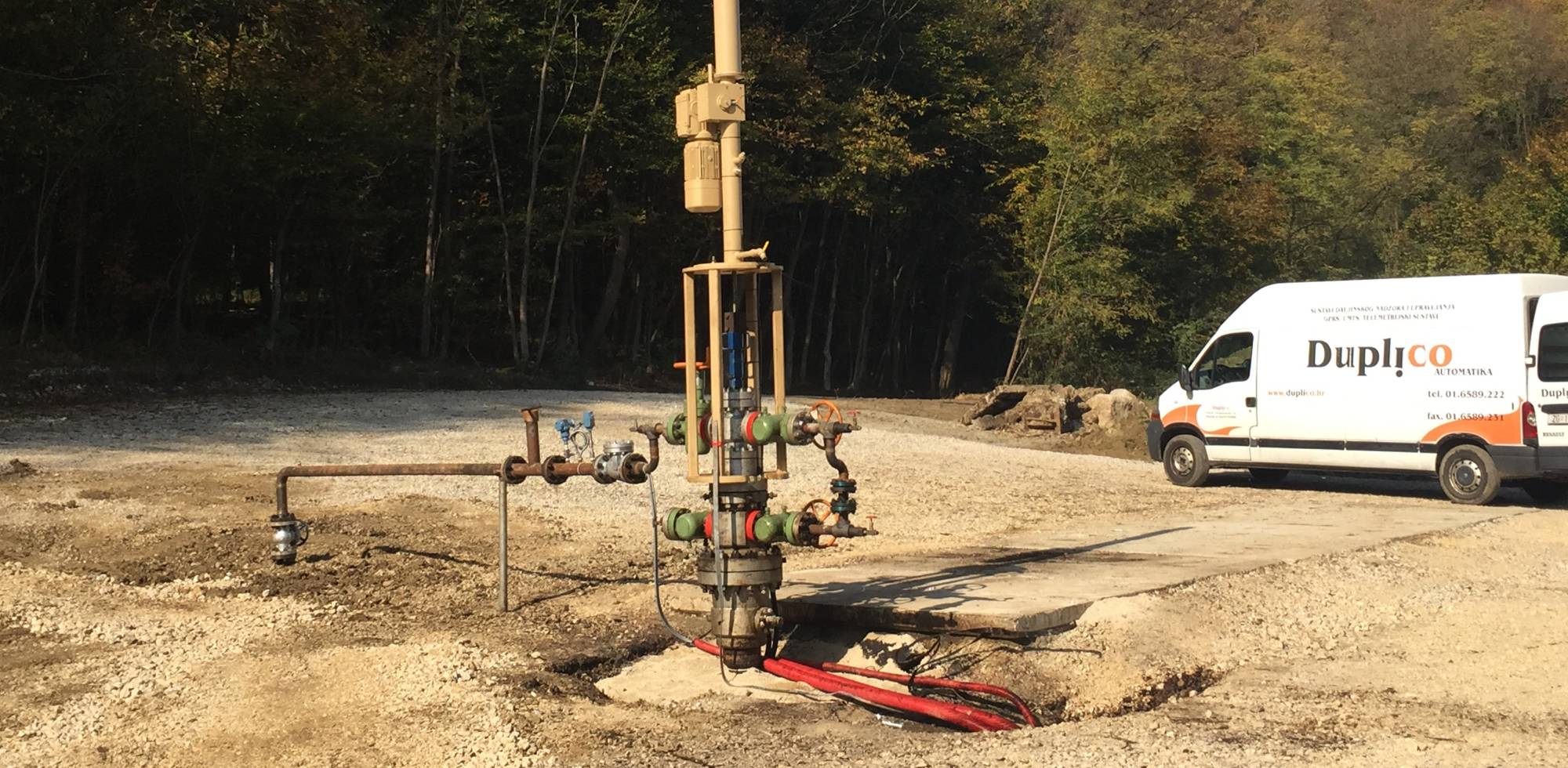

LRP (Linear Rod Pump) units are great alternatives to standard pumpjack units. LRP units enable competitive and safe production in a compact linear design.

The Linear Rod Pump units are patented technology from UNICO and as such, they have many advantages over the standard Sucker Rod Pumps horse-head look-alike units. Among others LRP units have minimal site impact, do not require a building permit, and are much easier to install and transport in case users want to move them. LRP Units can be easily fitted in any environment, including cities because of their small footprint.

They are an ideal solution for shallower wells, from which large units can no longer extract anything due to their constraints.

In combination with UNICO's patented sucker rod pump technology for autonomous oil well optimization, they represent a great alternative.

UNICO's LPR units are easier and cheaper to maintain because they come with advanced technology that requires zero sensors and all readings are done from the motor and VSD drives it itself.

Despite being sensorless they have all the features such as downhole equipment protection, fluid level controls, automatic pump clean mode, well reporting, surface and downhole predictive dynacards, remote access, and much more.

Duplico recognized this and in partnership with UNICO, we installed the UNICO LRP system in the Croatian Oil and gas company INA.

After the installation of 13 LRP units, the recorded oil production skyrocketed to 50%, making this project a huge success.

The valuable project information was a subject of a master thesis done by the University of Zagreb, Faculty and Mining, Geology, and Petroleum Engineering students, raising awareness of this technology even more.

Let's talk.

Do you have a project or need help to increase or automate your oil production?

Send us a message and some of our engineers will get back to you ASAP to discuss the project's requirements in further detail.