In electrical engineering, 3D modeling plays a pivotal role in creating efficient and precise electrical cabinet design.

This innovative approach not only ensures precision in design but also enhances the comprehension of complex systems, such as electrical cabinets. Some advantages of 3D modeling include error reduction during the design and manufacturing phases, resulting in time and resource savings while minimizing costs in subsequent stages.

In this article, we will explore how advanced technologies like EPLAN and CAD tools such as SolidWorks are transforming the processes of designing and manufacturing electrical cabinets.

Designing electrical cabinet schematics

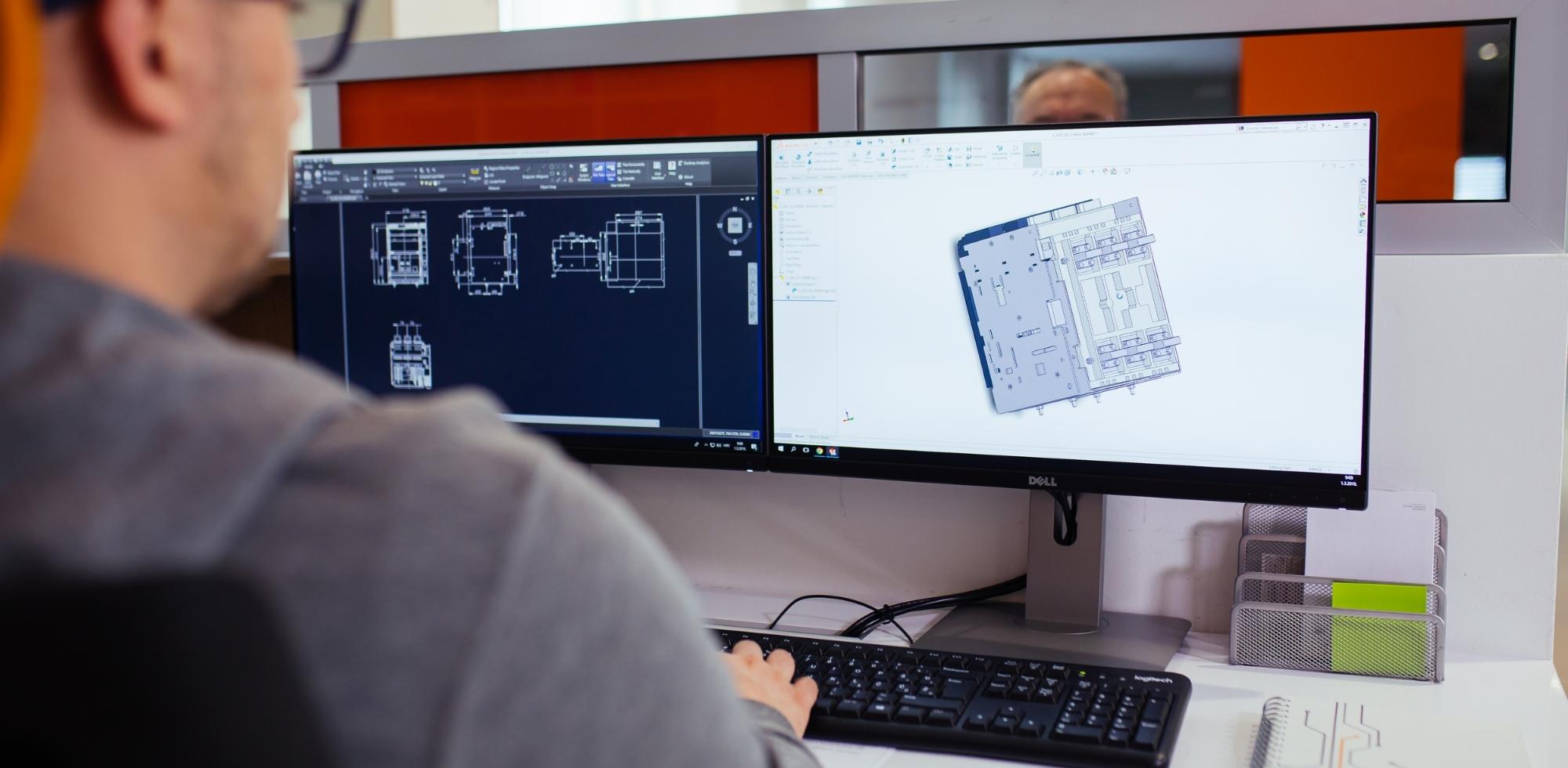

Designing and drawing electrical cabinet schematics are vital for creating precise electrical installations, forming the foundation for the successful execution of complex projects. To achieve accurate and detailed designs, sophisticated tools like EPLAN are employed.

The combination of advanced tools and approaches is fundamentally altering the way electrical cabinets become operational.

EPLAN

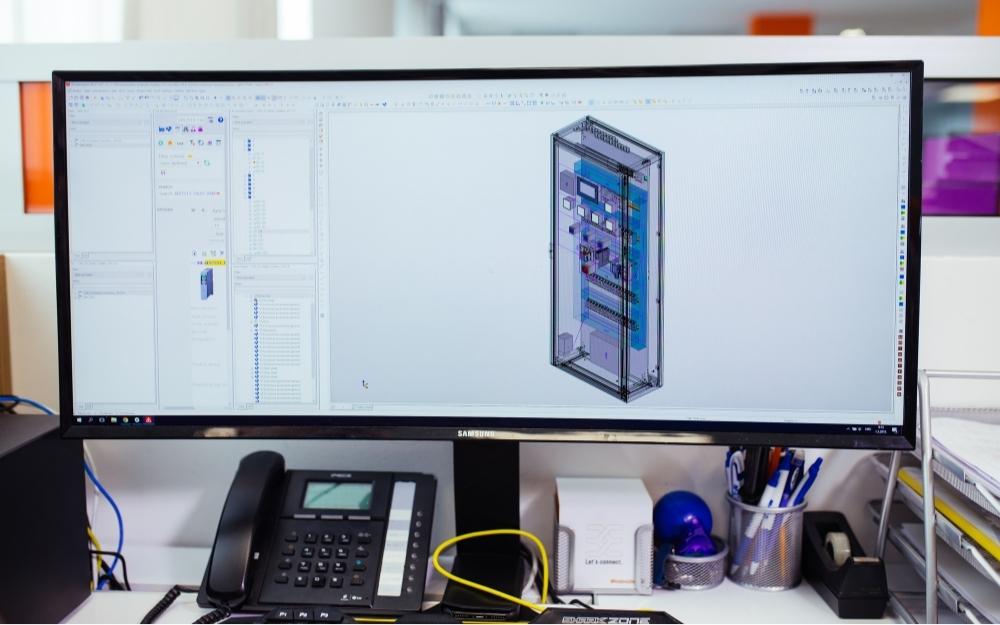

The EPLAN design platform enables the creation of precise and detailed designs for a wide range of projects. It visualizes complex systems in three dimensions, facilitating a better understanding of how each element fits and functions.

This approach is crucial in avoiding costly manufacturing errors, such as equipment relocation, additional drilling, or rewiring.

One of EPLAN's key features is the ability to create detailed electrical schematics with routing and dimensioning information. These are transferred to the "cloud" and transmitted to manufacturing facilities.

The same data is then used for the subsequent production processes on various machines, such as cable and wire cutting devices, CNC machines, and various equipment marking printers.

The digitalization and integration of key elements and stakeholders in the project provide a comprehensive framework for data control. This advanced approach not only accelerates the entire process but also minimizes human errors, ensuring cost-effectiveness and achieving the highest level of efficiency.

In situations where manufacturer components are not available in EPLAN's 3D model library, sophisticated tools like SolidWorks are used to create these components. Afterward, they are carefully integrated into the project, ensuring complete coherence and electrical cabinet design accuracy.

3D modeling of electrical cabinets

While EPLAN is primarily used for the visualization and design of electrical cabinets, 3D modeling through tools like SolidWorks aids in the precise depiction of their characteristics and construction.

3D modeling is a critical component of modern engineering processes, and in this context, SolidWorks stands out as a tool that allows engineers to create accurate 3D models of components and assemblies.

SolidWorks offers a range of capabilities, including sketching, extrusion, and the ability to import and manipulate 3D models from other software solutions, such as AutoCAD and Inventor. Moreover, SolidWorks provides advanced modeling tools, including surface modeling, sheet metal design, and welded connections.

This highly versatile tool is not confined to specific industries; its applications span various sectors, including mechanical engineering, manufacturing, and product design. Engineers working with SolidWorks can create 3D models of components with precise dimensions and specifications, laying the foundation for further electrical cabinet design and manufacturing.

Integration with EPLAN software allows the creation of comprehensive designs that meet our clients' needs. This enables engineers to create complex shapes and assemblies and accurately model component behavior under various loads and conditions.

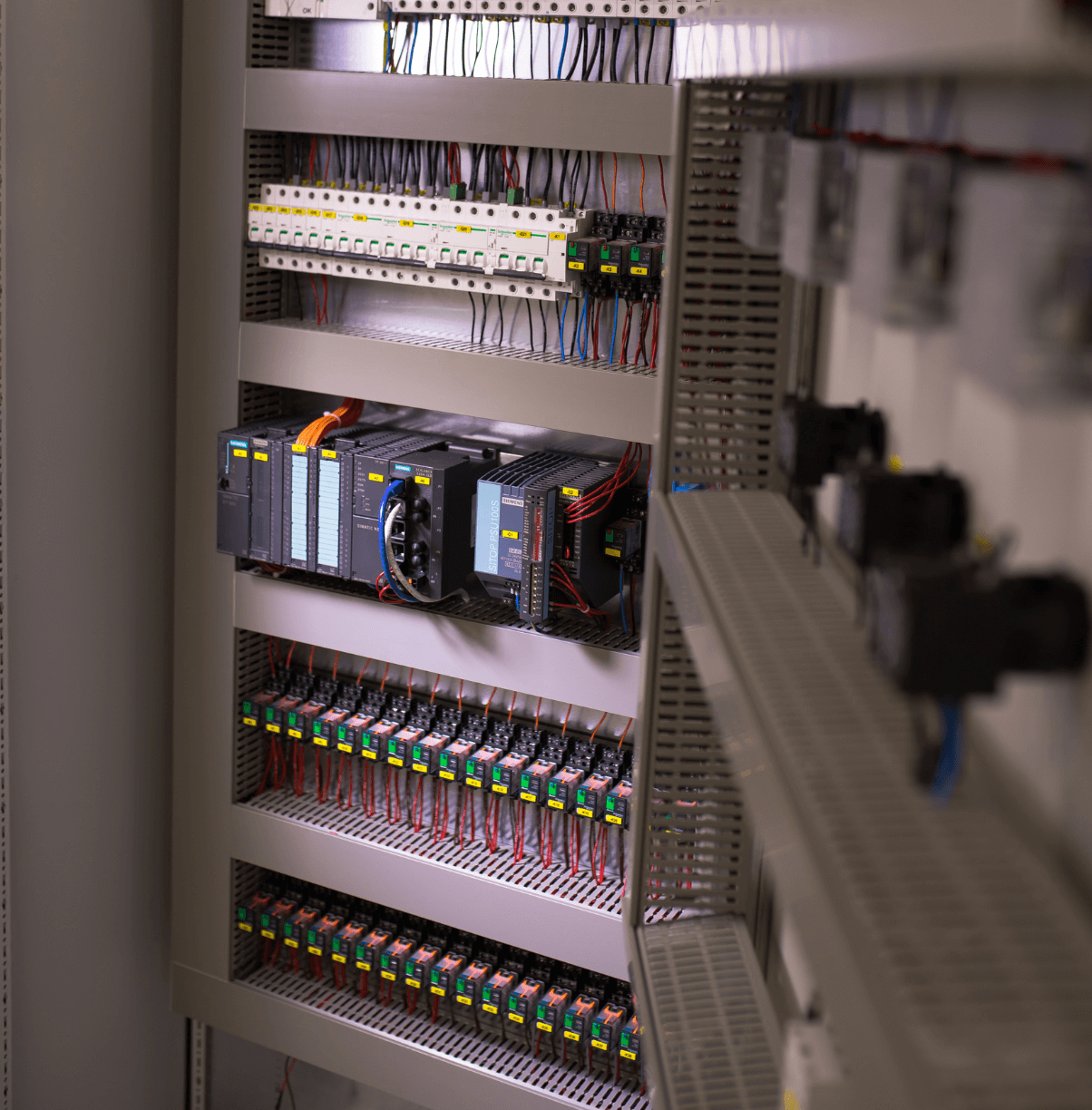

Duplico electrical cabinets

Precise 3D modeling plays a pivotal role in achieving energy efficiency and implementing advanced control solutions, especially in the realm of control electrical cabinets.

Our team utilizes various 3D design software, including SolidWorks and proprietary software that tracks every aspect of production, quality control processes, and testing by HRN EN 62208 standards.

Advanced 3D modeling and the integration of sophisticated tools enable us to ensure flawless design and manufacturing, adhering to the highest standards and meeting our client's requirements.