Achieving an exceptionally high level of efficiency and productivity is imperative for the survival and competitiveness of companies. In this context, the automation of industrial processes through PLCs (Programmable Logic Controllers) plays a crucial role.

PLCs, as an indispensable component in many industries, are revolutionizing how systems are produced, monitored, and managed. Their widespread application and numerous advantages set new standards for improving efficiency and productivity, playing a pivotal role in industrial environments.

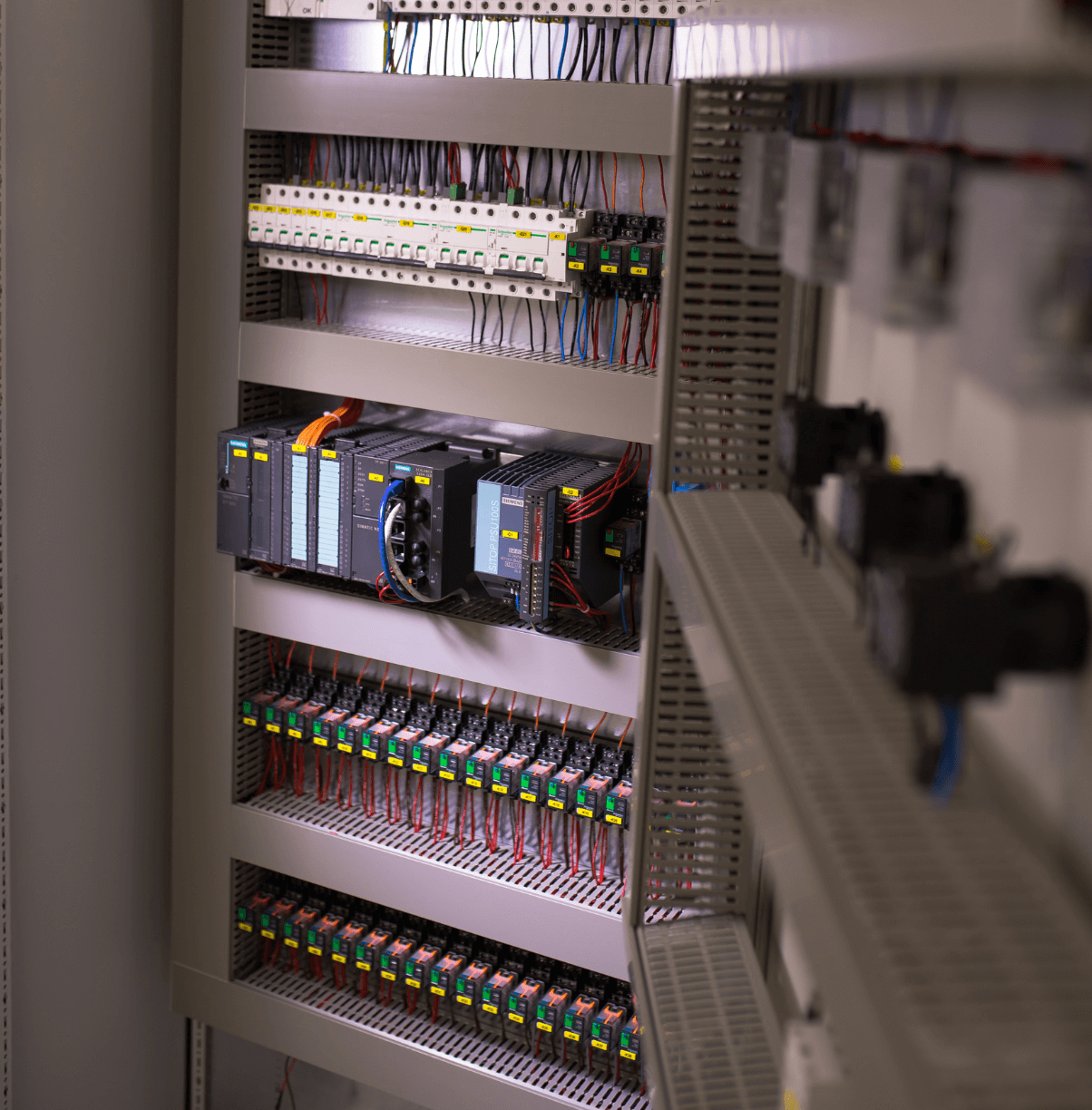

PLC control systems: the core of industrial automation

Programmable Logic Controllers (PLCs) are advanced electronic devices designed to precisely control, monitor, and automate various electromechanical processes in industry. PLCs use complex logic and programmable algorithms to enable defined actions and operations, significantly enhancing the efficiency and reliability of industrial systems.

Their remarkable flexibility and adaptability allow the control and automation of various electromechanical processes. They not only simplify specific tasks and machine functions but also automate production lines.

They are applied in various sectors, including manufacturing, energy, transportation, as well as energy production and distribution. Their presence and ability to operate in diverse industries contribute to increased efficiency and productivity in industrial operations.

PLCs have become an indispensable tool in modern environments, enhancing performance and ensuring the stability of industrial processes.

Advantages of PLC control systems

1. Process automation

Automation through PLCs not only significantly reduces the need for physical labor but also increases precision in executing critical tasks. Through this technology, companies can optimize their production operations, resulting in competitive products and a stronger market position.

2. Precise control

PLCs enable real-time process control, greatly increasing the accuracy of operations and significantly reducing the risk of human errors. This ability for precise control makes them a key tool for achieving consistently high standards of quality and efficiency.

3. Increased productivity

Integrating PLCs enhances the productivity of industrial operations, significantly reducing the time required to complete tasks. This acceleration of processes allows companies to achieve more efficient results within the same time frame.

4. Flexibility and adaptability

PLCs stand out for their ease of programming and quick adaptation to changes in production. This feature makes them ideal for various industrial sectors and requirements, enabling companies to swiftly adjust to new challenges and market demands.

5. Safety control

PLCs can also integrate key safety features to ensure the complete protection of workers and equipment, significantly improving workplace safety. This capability makes them fundamental for ensuring secure and reliable operations in industrial settings.

Application of PLCs in various industries

Manufacturing sector

In the manufacturing sector, PLCs optimize production processes, helping reduce waste, increase production speed, and improve product quality. For example, in the automotive industry, PLCs coordinate robots and assembly lines to make production faster and more precise.

Energy industry

In the energy sector, PLCs enable the control and monitoring of energy facilities, including electricity production and distribution. This ensures the stability of the electrical power system and promotes efficient resource utilization.

Transportation

In the transportation sector, PLCs take control of signaling and traffic management systems, actively contributing to optimizing road traffic and ensuring safe and smooth vehicle flow.

Energy distribution

In the electric power distribution sector, PLCs play a critical role in managing smart grids. Their ability to quickly detect and automatically intervene in case of network issues significantly reduces the risk of power outages, ensuring continuity and reliability in energy distribution.

In each of these sectors, PLCs bring tangible benefits in the form of increased productivity, better control, cost reduction, and resource optimization. These systems are pivotal for the modernization of various industrial sectors, enabling them to remain competitive in today's dynamic environment.

The future of automation

With incredible technological advancements, we can expect the intensified application of PLCs in industrial automation. Proactively adopting PLC technology significantly helps companies maintain competitiveness in today's highly dynamic business environment.

PLC systems are beneficial for companies as they provide high reliability in automating industrial processes, and minimizing errors and breakdowns. They are also compact and space-saving compared to traditional control systems. Through simple configuration, they allow customization and specialization, granting companies flexibility in manufacturing.

Duplico engineers undergo thorough education and professional development to work with leading PLC suppliers in the industry. Our control systems are based on technologies from renowned manufacturers such as Schneider Electric, Mitsubishi, Allen Bradley, Phoenix, and Siemens.

We are dedicated to ensuring top quality and expertise in our approach to industrial automation.