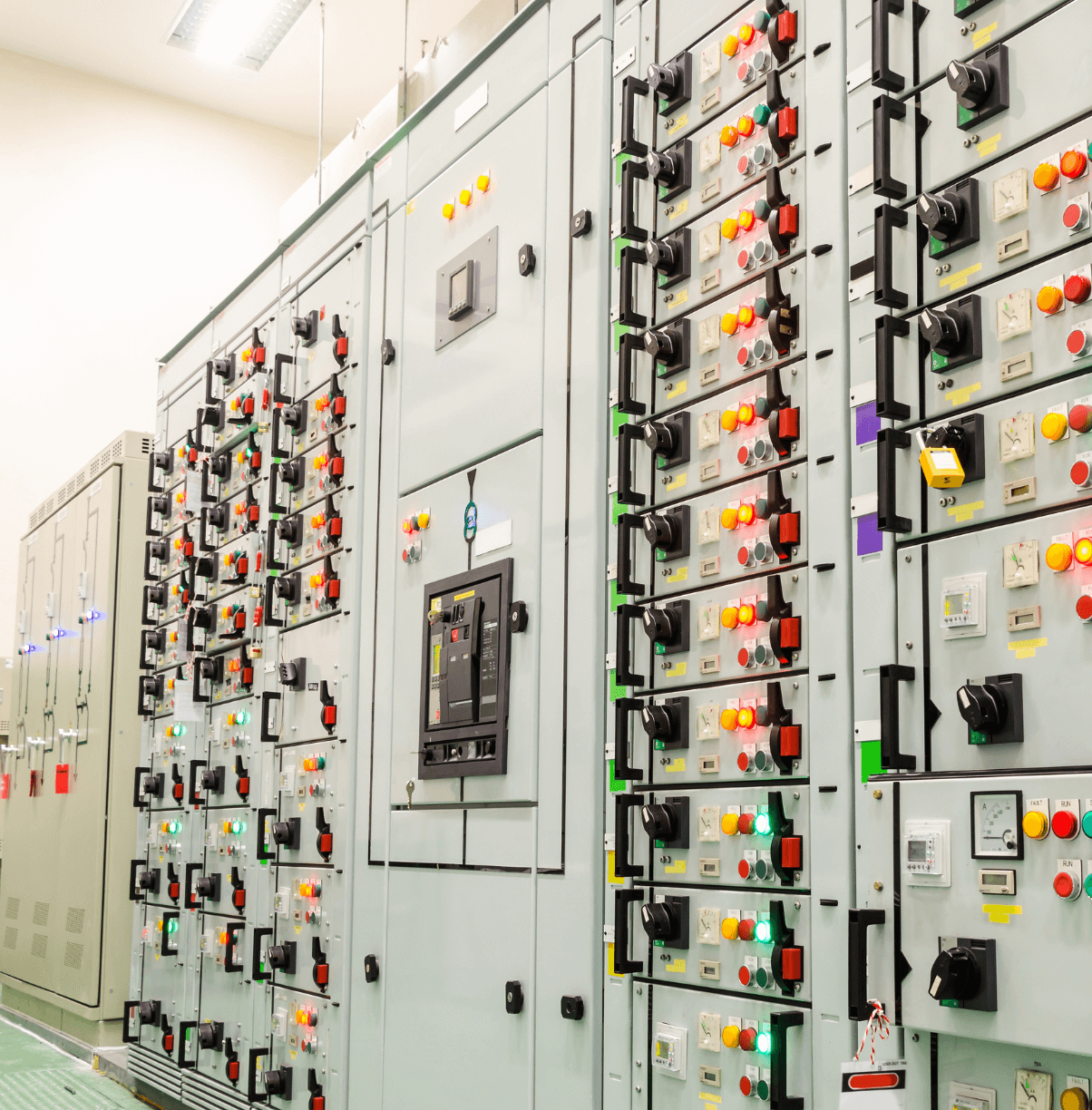

We are thrilled to announce the publication of our groundbreaking research paper in the prestigious IEEE (https://ieeexplore.ieee.org/document/10105199?source=authoralert) journal, presenting an innovative technology for the production of electrical cabinets using laminated conductors.

This cutting-edge approach promises to revolutionize the industry by offering significant size reduction, simplified usage, and improved installation.

Our research paper introduces a new method based on the alternating stacking of conductive and insulating layers, which allows for the fully automated production of electrical cabinets using laminated conductors with rectangular cross sections.

This unique approach eliminates the need for traditional wiring techniques and offers numerous advantages over conventional cabinet production methods.

A Breakthrough Research

The application of laminated conductors in electrical cabinet production brings a range of benefits that are set to redefine the industry.

Our research indicates that this new technology can reduce the size of electrical cabinets by up to 70%, enabling more efficient use of space and streamlined integration into various settings. Moreover, the simplified design and installation process enhance usability and reduce the complexity of cabinet deployment.

To assess the feasibility and advantages of the proposed technology, we conducted extensive thermal and mechanical simulation analyses. The simulations allowed us to evaluate the performance of the laminated conductors under various operating conditions, ensuring their reliability and efficiency.

Duplico DxL prototype.

Furthermore, we developed a prototype and conducted comprehensive electrical and mechanical functionality tests to validate the practical application of the technology. The results obtained from the experiments provided concrete evidence of the effectiveness and potential of our approach.

The findings presented in our research paper have far-reaching implications for the field of electrical cabinet production. This innovative technology has the potential to transform the industry by introducing a more efficient, compact, and user-friendly solution.

The size reduction and improved functionality open up possibilities for diverse applications in the energy, manufacturing, transportation, and food and beverage sectors.

Moving forward, we are dedicated to further optimizing and refining this technology. We envision collaborations with industry partners to explore practical implementations and capitalize on the advantages offered by laminated conductors.

Our research serves as a foundation for future advancements in electrical cabinet production, paving the way for enhanced efficiency, reduced costs, and increased sustainability.

Electrical cabinet research published in IEEE

Our research paper published in IEEE presents a groundbreaking technology for electrical cabinet production using laminated conductors.

The innovative approach based on alternately stacked conductive and insulating layers offers significant advantages in terms of size reduction, simplified usage, and improved installation.

Our simulation analyses and experimental validation confirm the feasibility and potential of this technology, marking a significant advancement in the field.

We believe that this breakthrough will shape the future of electrical cabinet production and contribute to the evolution of the industry as a whole.