In the energy and automation systems sector, control electrical cabinets are indispensable for the safe management of industrial facilities.

Their purpose is to protect equipment, machinery, and their complex components, ensuring seamless and safe operation in industrial facilities. Additionally, monitoring and controlling critical parameters through these cabinets contribute to minimizing the risk of accidents, thereby preserving the safety and productivity of the entire industrial operation.

What are control electrical cabinets used for?

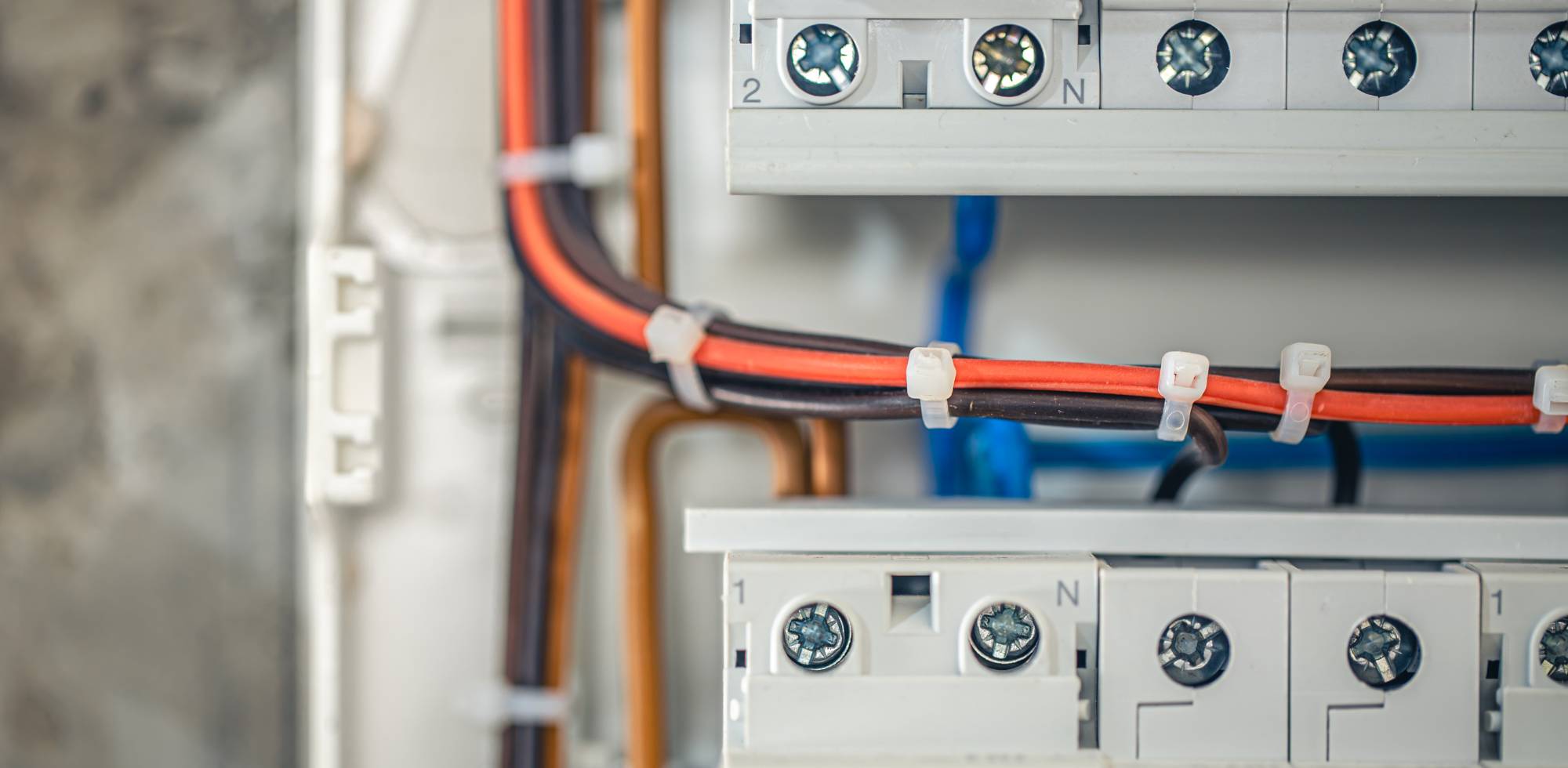

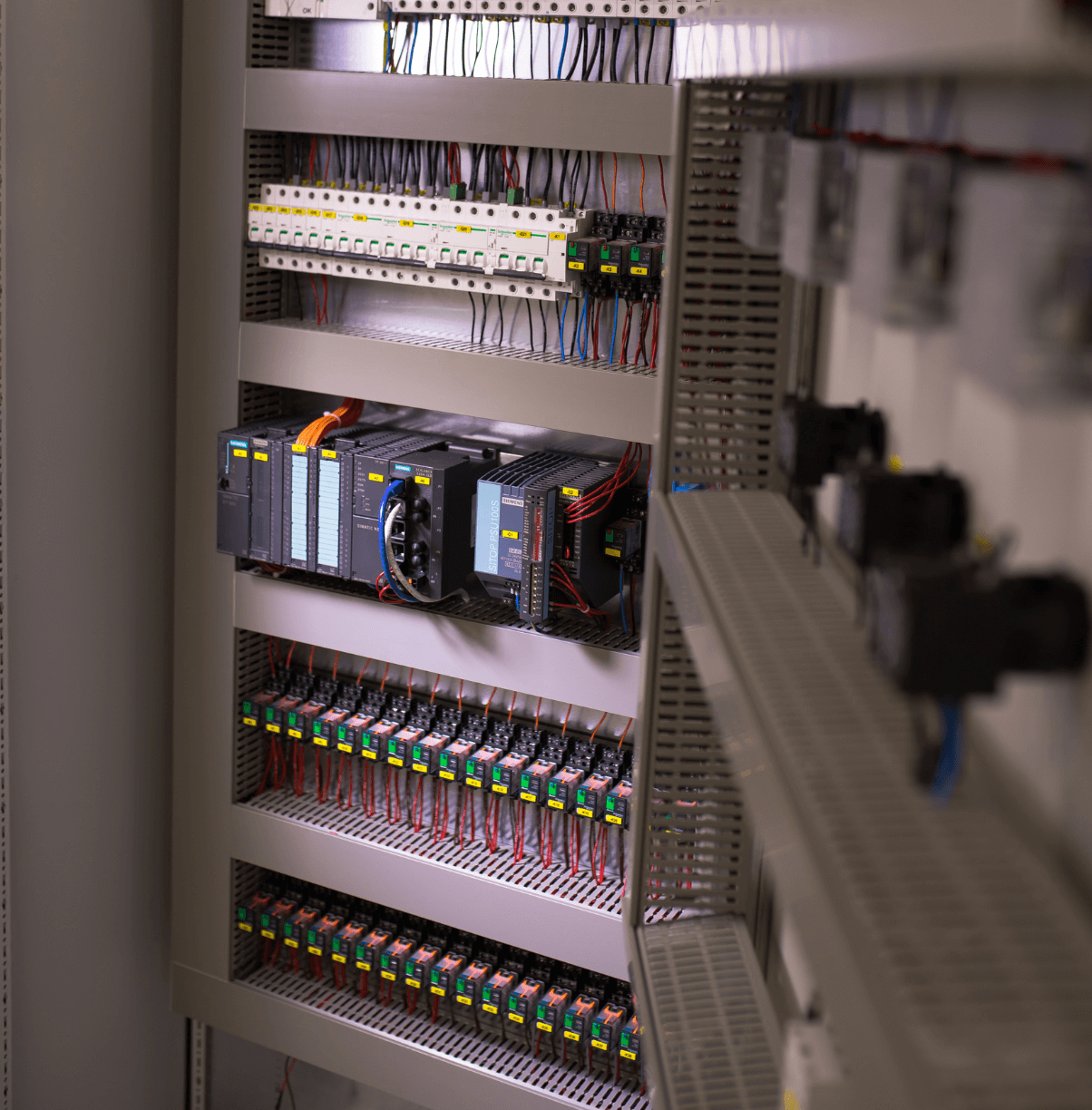

Control electrical cabinets are enclosures that house equipment and components for controlling and managing industrial processes. Furthermore, they contain controllers, switches, relays, sensors, communication equipment, and other components that enable automation and supervision of various processes within a facility.

Control electrical cabinets facilitate the management of complex systems involving different components, aiming for precise and optimal performance.

The efficiency of these cabinets makes them an essential part of modern manufacturing processes, assisting organizations in achieving efficiency, competitive advantages, and compliance with the highest quality and safety standards.

The key role of control electrical cabinets in risk management

1. Worker and facility safety

Electrical cabinets contain various electrical components, such as fuses and safety switches, that protect personnel and essential assets from electrical faults, including short circuits and overloads. These components prevent fires, equipment damage, and potential harm to workers.

Properly designed and executed electrical cabinets ensure that electrical circuits are protected from overheating, short circuits, and other issues that could lead to fires or worker injuries.

2. Reducing the risk of failures in facilities

Control electrical cabinets play a crucial role in ensuring consistent and precise managing of the work processes in industrial facilities. Any malfunctions or interruptions in the operation of electrical cabinets can result in production downtime and significant resource losses.

Furthermore, electrical cabinets enable a quick diagnosis and problem resolution, reducing the risk of production interruptions and saving time and resources for the organization.

3. Adaptability and optimization of industrial processes

Control electrical cabinets enhance the optimization and flexibility of industrial processes by offering automation, and remote monitoring capabilities. They allow operators to make rapid adjustments based on real data, reducing the need for interventions and ensuring consistent and efficient workflows.

Integration with information systems and features for energy management further contributes to process optimization, while security protocols and predictive maintenance functions help prevent accidents and unexpected disruptions.

In summary, control electrical cabinets are critical components of modern industrial operations that promote efficiency and adaptability.

4. Ensuring quality and safety

The production of electrical cabinets adheres to stringent industrial standards and manufacturing procedures. These enclosures must be well-sealed, durable, and protected against corrosion, moisture, and extreme temperatures.

Selecting products from reputable manufacturers is crucial to ensure the highest level of safety, reliability, and top-notch performance for your investment in control electrical cabinets.

Electrical cabinets play a crucial role in improving efficiency and safety. As industries continue to evolve, they remain essential resources that ensure the smooth operation of machinery and systems worldwide.

5. Energy efficiency of control electrical cabinets

Control electrical cabinets plays a key role in achieving energy optimization through careful management of electric power. This function is of paramount importance, especially for industries focused on reducing energy consumption.

By appropriately distributing and using energy, control cabinets not only contribute to cost savings but also align industrial operations with sustainability goals. Moreover, they enable the implementation of energy efficiency technologies and strategies, ensuring that industrial facilities operate in an environmentally responsible manner while enhancing overall operational efficiency.

The importance of certified control electrical cabinets

The significance of certified electrical cabinets lies at the core of safety and success in industrial operations. Through this secure and reliable infrastructure, electrical systems operate flawlessly, guaranteeing maximum productivity and minimal risk of unexpected interruptions.

Collaborating with certified electrical cabinet manufacturers provides customers with competitive advantages, helping them meet strict industry regulations and standards. This collaboration also provides access to the latest technical support and training, ensuring that personnel are well-equipped to maintain and operate the equipment.

All these advantages together form the foundation for long-lasting and fruitful relationships with key clients and strategic partners, which are crucial for successful operations in today's demanding business environment.