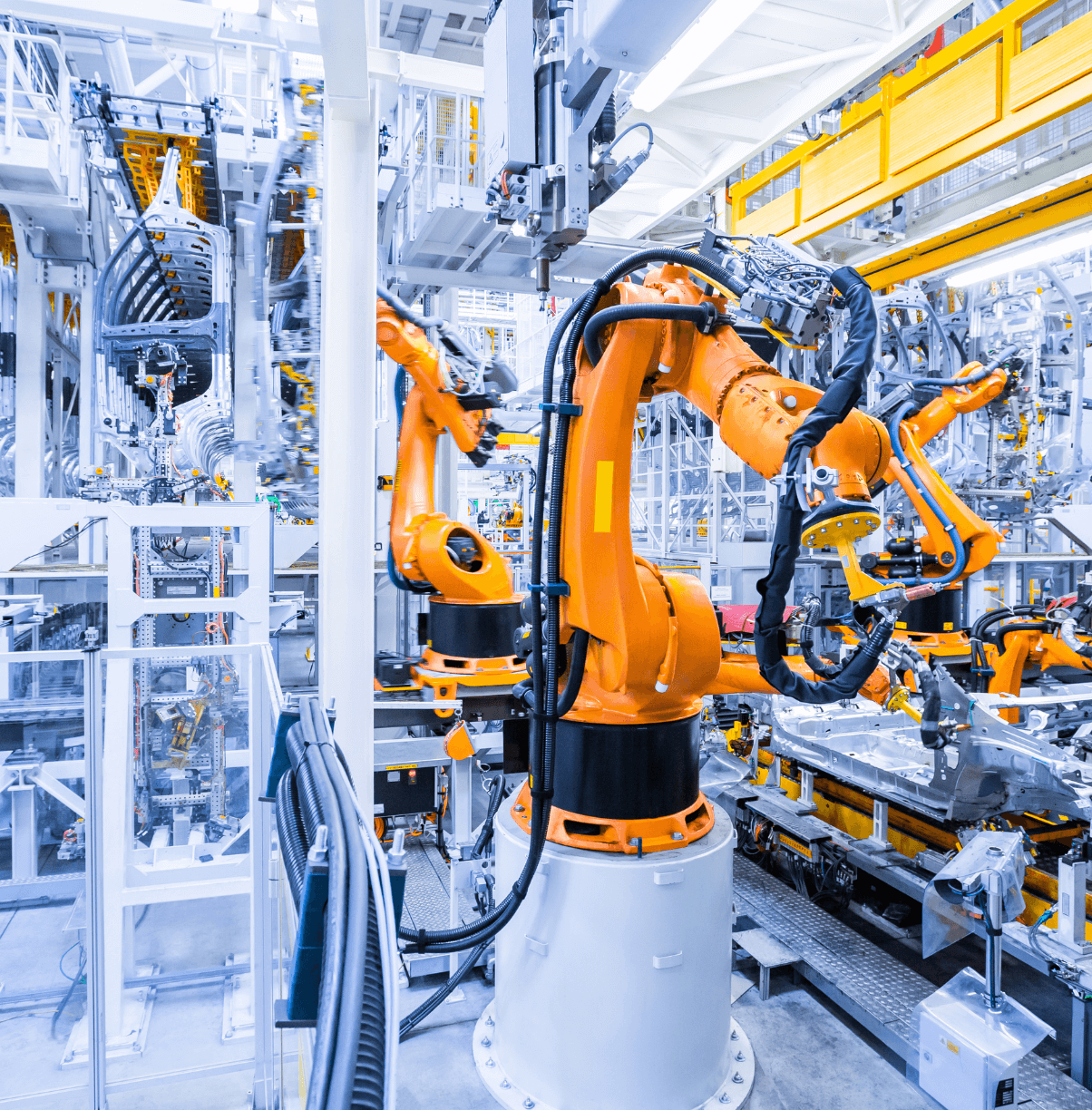

Interconnection between automation and robotics

Automation and robotization are completely intertwined while robots are the executive organs of automation.

Automation and robotization are closely related concepts that are often used in the manufacturing and production industries to improve efficiency and productivity. Automation refers to the use of technology to automatically control and monitor industrial processes, such as assembly lines and machine tools.

This can be achieved through the use of programmable logic controllers (PLCs), which are computerized systems that use sensors and other inputs to make decisions about how to control a process.

Robots, on the other hand, are mechanical or electromechanical devices that are programmed to perform tasks automatically.

They can be used in a variety of applications, including manufacturing, assembly, inspection, and material handling. Robots can be programmed to perform a wide range of tasks, from simple tasks such as welding or painting to more complex tasks such as assembling electronics or packaging products.

In many cases, automation and robotization are used together to create highly efficient and productive systems. For example, an automated assembly line might use robots to perform tasks such as welding or painting, while a programmable logic controller (PLC) coordinates the movements of the robots and ensures that the process is running smoothly.

This can help to increase the speed and accuracy of the manufacturing process, as well as reduce the need for human labor.

Modern society and the 4th industrial revolution are moving in the direction of meeting standards and replacing humans at every step, in every process, as far as possible in terms of quality.

Definition of automation

Automation of industrial processes refers to the automatic production of goods with the help of robots and control systems to reduce human work in production facilities as much as possible. Automation most often includes robotization of production, in which robots perform specific tasks.

Automation is often used in manufacturing and production industries to improve efficiency, reduce the need for human labor, and increase the accuracy and consistency of the production process. Automation can be achieved through the use of various types of technology, including robotics, computerized systems, and sensors, to control and monitor different aspects of the production process.

In addition to robots, automation includes the use of artificial intelligence, the industrial Internet of Things, the use of 3D technologies, and many other advanced technologies.

In the future, automation will enable new opportunities such as the development of new and advanced technologies that companies will increasingly implement to keep up with market changes.

Companies nowadays use the automation of industrial processes to optimally manage production costs. Automation of industrial processes reduces the possibility of errors and therefore saves time.

Furthermore, the advantage of automated processes is that it is easy to monitor progress and spot errors so that the procedure is as fast and high-quality as possible.

Automation of industrial processes enables high-quality management of business processes both at the level of individual departments and at the level of the entire company. Duplico has been dealing with automation since its very beginning.

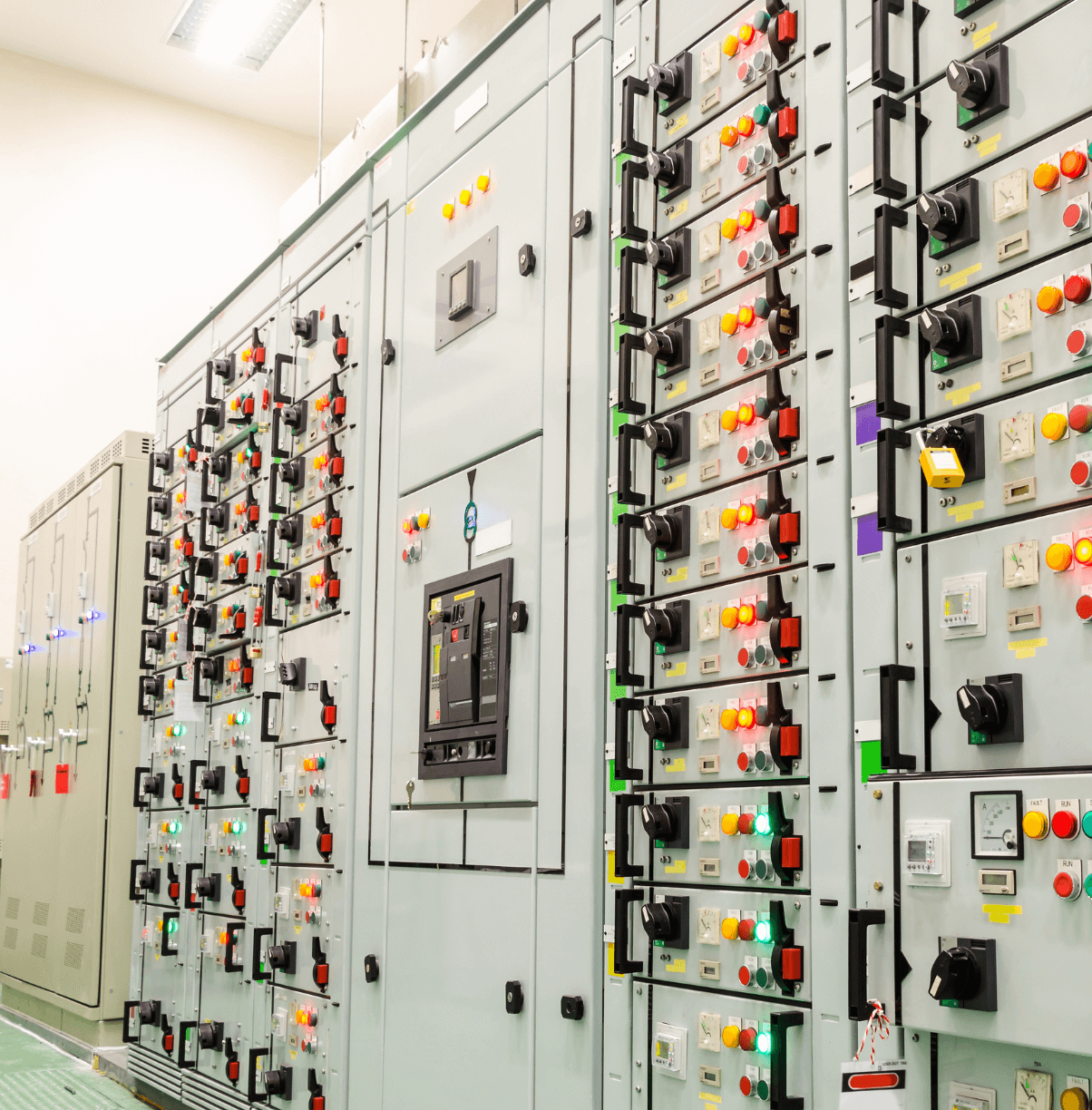

The symbiosis of utility automation systems with telemetry

Automation systems in the utility infrastructure, such as the electricity, gas, and water networks, can be used to improve the efficiency and reliability of these vital services.

These systems often involve the use of sensors, programmable logic controllers (PLCs), and other technologies to monitor and control various aspects of the utility infrastructure.

For example, automated control systems can be used to adjust the flow of electricity or water in response to changes in demand, or to remotely monitor and control the operation of pumps, valves, and other equipment.

Telemetry or the remote measurement and reporting of data are often used in conjunction with automation systems in the utility infrastructure.

Telemetry systems can be used to transmit data about the performance and operation of the utility infrastructure in real time, allowing operators to monitor and control the system remotely.

This can be especially useful in remote or difficult-to-access locations, where it may be impractical to manually monitor and control the system.

Overall, the use of automation and telemetry systems in the utility infrastructure can help to improve the reliability, efficiency, and safety of these critical services.

Duplico has patented its method of safe transmission of telemetry data with FTP, UDP, TCP/IP, and MODBUS over TCP/IP protocol in mobile GPRS, EDGE, and UMTS networks to the static IP address of the server in GPRS, EDGE, UMTS, VPN and internet network in gas supply that has found a wide application.

SCADA

SCADA (Supervisory Control and Data Acquisition) is a software or application that serves to display the state of the factory. The correct way of using such applications achieves proper display and management of the factory.

The task of the SCADA developer is to visualize the factory and process and show the user its state in a proper, simple and purposeful way.

Industrial process automation depends on software like SCADA.

Namely, SCADA software is special because it provides information in real time so that processes and operations are efficient, reliable, and safe. In addition, large amounts of data can be stored using SCADA software and it connects a large number of sensors for remote process monitoring.

SCADA software is used to automate industrial processes where human control is limited. For example, water supply, industrial production, electricity production, and many other industrial areas.

Thus, the SCADA software only displays information, whilst PLC (Programmable Logic Controller) provides the commands for the plant.

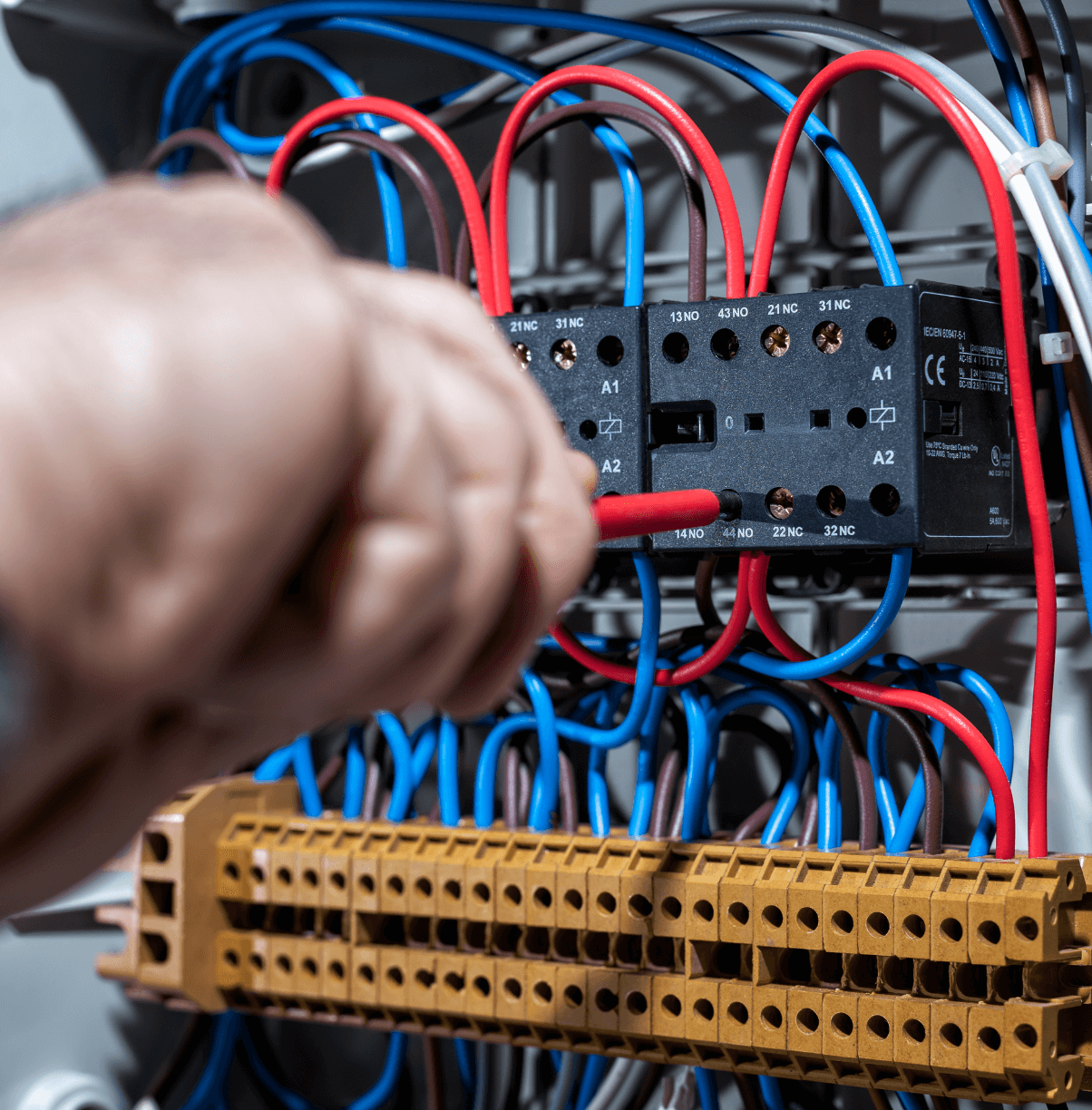

PLC

Programmable Logic Controllers (PLCs) are computerized systems that are used to control and automate industrial processes, such as assembly lines, machine tools, and other manufacturing equipment.

PLCs use a set of inputs (such as sensors and switches) and a set of outputs (such as motors and valves) to control a process based on a set of predetermined rules or logic.

PLCs are often used in manufacturing and production industries to improve efficiency, reduce the need for human labor, and increase the accuracy and consistency of the production process.

They can be programmed to perform a wide range of tasks, such as controlling the speed and direction of motors, activating alarms or warning systems, and controlling the flow of fluids or gases.

PLCs are highly reliable and can operate continuously for long periods, making them well-suited for use in industrial environments. They are also easily programmable and can be configured to perform different tasks or respond to different inputs as needed, making them highly flexible and adaptable.

Automation through SCADA and PLC

Automation of industrial processes requires software such as PLC.

The PLC program is used to control machines and equipment in the plant. PLCs are often used in industries because they are easy to program and provide prompt and accurate information on a fully automated system from start to finish.

The technologies used before PLCs were slow and often involved human error.

However, a PLC can handle a large number of tasks at the same time and provides real-time feedback. This software processes data in a fast way, and with it, engineers receive timely information from great distances.

There are several key benefits to using automation through Supervisory Control and Data Acquisition (SCADA) systems and Programmable Logic Controllers (PLCs) in industrial and manufacturing environments:

1. Improved efficiency

Automation can help to improve the efficiency and productivity of industrial processes, as it allows machines and equipment to operate with a high degree of accuracy and consistency. This can help to reduce the need for human labor and increase the overall efficiency of the production process.

2. Increased accuracy

Automation can help to reduce the potential for errors and improve the accuracy of industrial processes. For example, PLCs can be programmed to perform tasks with a high degree of precision, and SCADA systems can provide real-time data that can be used to monitor and control the process.

3. Improved safety

Automation can help to improve safety in industrial environments by reducing the need for humans to work in hazardous areas. For example, robots can be used to perform tasks that might be dangerous for humans, such as welding or painting.

4. Enhanced flexibility

Automation systems can be easily reconfigured or modified to perform different tasks or respond to different inputs, making them highly flexible and adaptable to changing needs or requirements.

5. Reduced costs

Automation can help to reduce the cost of industrial processes by reducing the need for human labor and increasing the efficiency of the production process. This can help to lower the overall cost of goods and services produced in the industry.

Our approach to users is characterized by defining, noticing, and reacting to the peculiarities of each observed process/area, and the result is unified services that satisfy a wide range of users. By our business principles,

Duplico can offer its modernization and process automation services to the oil, food, pharmaceutical industries, heating industry, energetics, building industries, and communal activities (water supply, drainage, purifiers, and gas distribution).

SCADA licencing

We have been licensed by and are an authorized partner for several SCADA systems: Aveva System Platform, Siemens WinCC, General Electric iFix, and PcVue.

Licensing to use various SCADA systems, ensures that the use of the systems is legal and in compliance with the terms of the license agreement.

SCADA systems are important tools for automating and controlling industrial processes and having access to a range of different systems provides you flexibility and options when it comes to choosing the right system for clients' needs.

- Aveva System Platform is a comprehensive SCADA system that is used in a variety of industries, including oil and gas, power generation, and water and wastewater. It offers a range of features, including real-time data visualization, remote monitoring and control, and integration with other systems.

- Siemens WinCC is a powerful SCADA system that is used in a wide range of industries, including manufacturing, energy, and transportation. It offers a range of features, including real-time data visualization, alarm management, and integration with other systems.

- General Electric iFix is a SCADA system that is used in a variety of industries, including manufacturing, utilities, and oil and gas. It offers a range of features, including real-time data visualization, alarms and event management, and integration with other systems.

- PcVue is a SCADA system that is used in a variety of industries, including energy, transportation, and manufacturing. It offers a range of features, including real-time data visualization, alarm management, and integration with other systems.

Overall, access to a range of different SCADA systems can provide us with flexibility and numerous options when it comes to automating and controlling industrial processes to attend to each client's needs.