Installation, Automation & Commissioning

We successfully delivered a comprehensive solution designed for the oil and gas industry to improve the production of oilfields in the Republic of Croatia. The project encompassed three existing oilfields: Ivanić Grad, Žutica, and Ladislavci, where our main goal was to enhance the production capabilities and efficiency of 13 wells by implementing LRP (Linear Rod Pump) Artificial lift systems.

To address the project requirements, we collaborated closely with the client - INA, to design LRP systems tailored to their specific needs. Our team analyzed the oil well characteristics, production targets, and safety standards to create a customized LRP system design that would optimize performance and meet the set objectives.

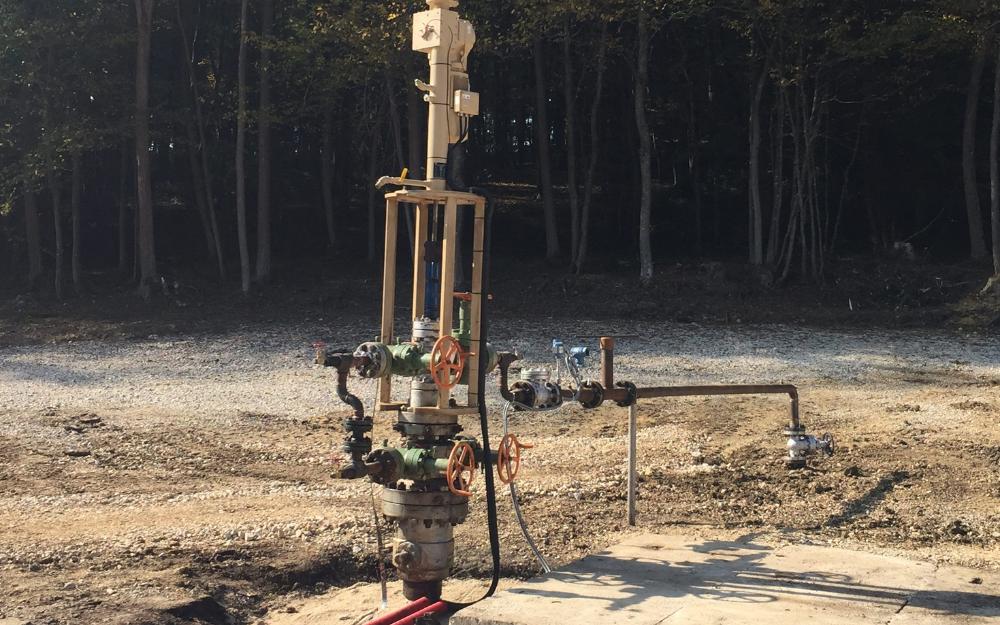

Following the design phase, we ensured the timely delivery of the LRP systems, together with all the necessary components and equipment. This included both LRP units and the essential VFD (Variable Frequency Drive) cabinets. The cabinets provide precise control over the speed and operation of electric motors within the LRP systems, which contributes to the efficient and increased production of oil.

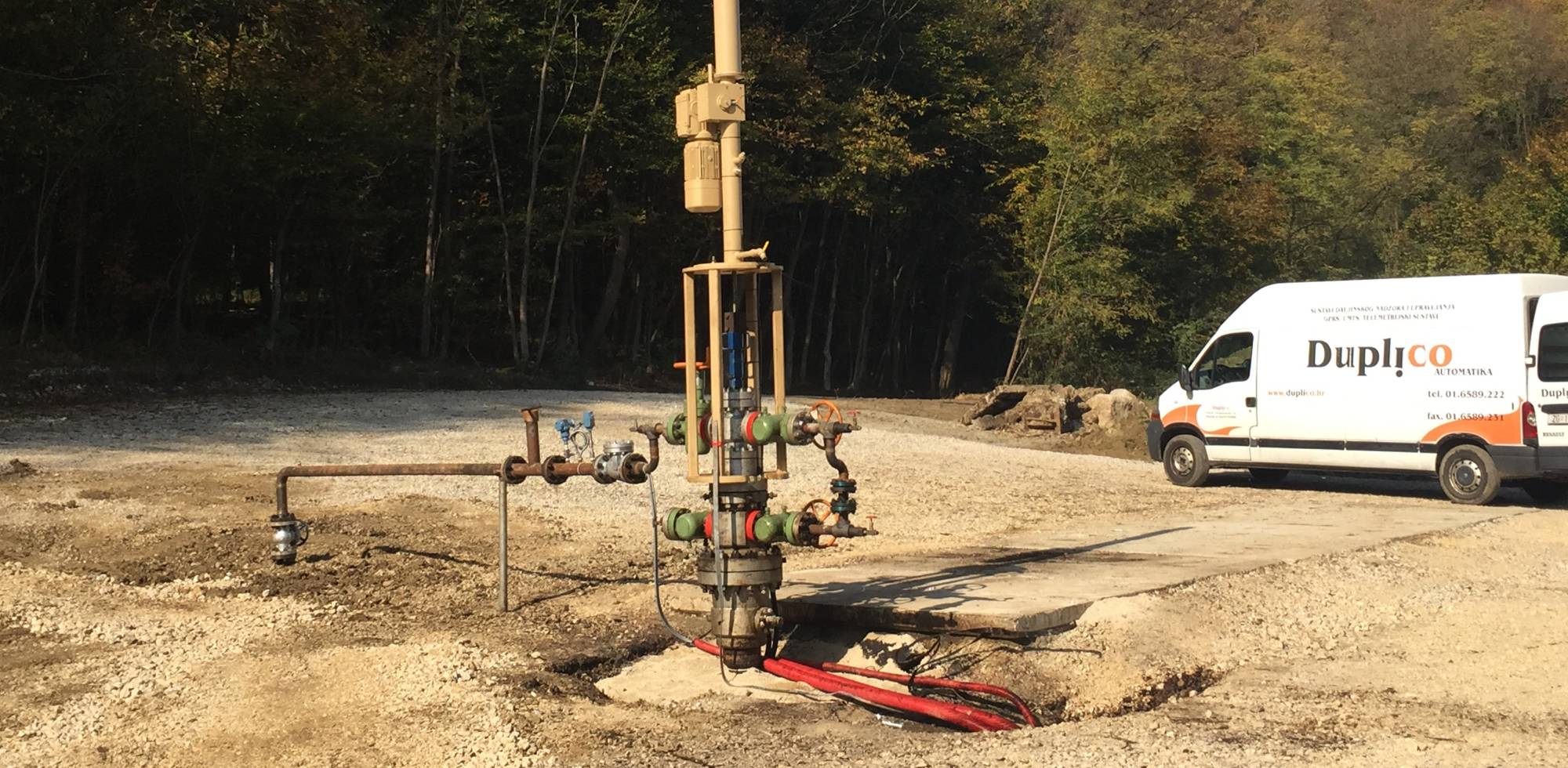

The complete scope of execution of the installation of the LRP systems on designated wells performed by the Duplicos installation team included positioning and configuration of designated equipment such as valves, pumps, flow meters, and integration for optimal functionality of LRP systems.

The team also enrolled in thorough commissioning activities that followed the installation including comprehensive testing and verification of LRP systems performance to guarantee the operation to follow the design specifications.

Additionally, a Site Acceptance Test (SAT) was conducted, where we rigorously assessed the systems' compliance with INA's expectations and industry standards, ensuring their readiness for production operations.

An integral part of the project, we have also provided and installed an LRP controller equipped with specialized software integrated into the overall system architecture. The controller serves as the central hub for monitoring and control of LRP systems, enabling real–time data analysis, system optimization, and enhanced operational efficiency.

The LRP solutions implementation also involved extensive training programs for clients' engineers and LRP operators, ensuring their comprehensive proficiency. The training sessions covered various operational aspects, including system operation, maintenance procedures, troubleshooting techniques, and safety protocols. By equipping the client's team with the necessary knowledge and skills, we ensured that they could effectively manage, operate, and maintain the LRP systems, thereby maximizing their performance and longevity.

Throughout the entire project process, we showcased dedication to delivering high-quality solutions for the oil and gas industry.

By providing a comprehensive package that encompassed system design, equipment delivery, professional installation, commissioning, and training, we enabled INA to enhance the production capabilities of the oilfields.