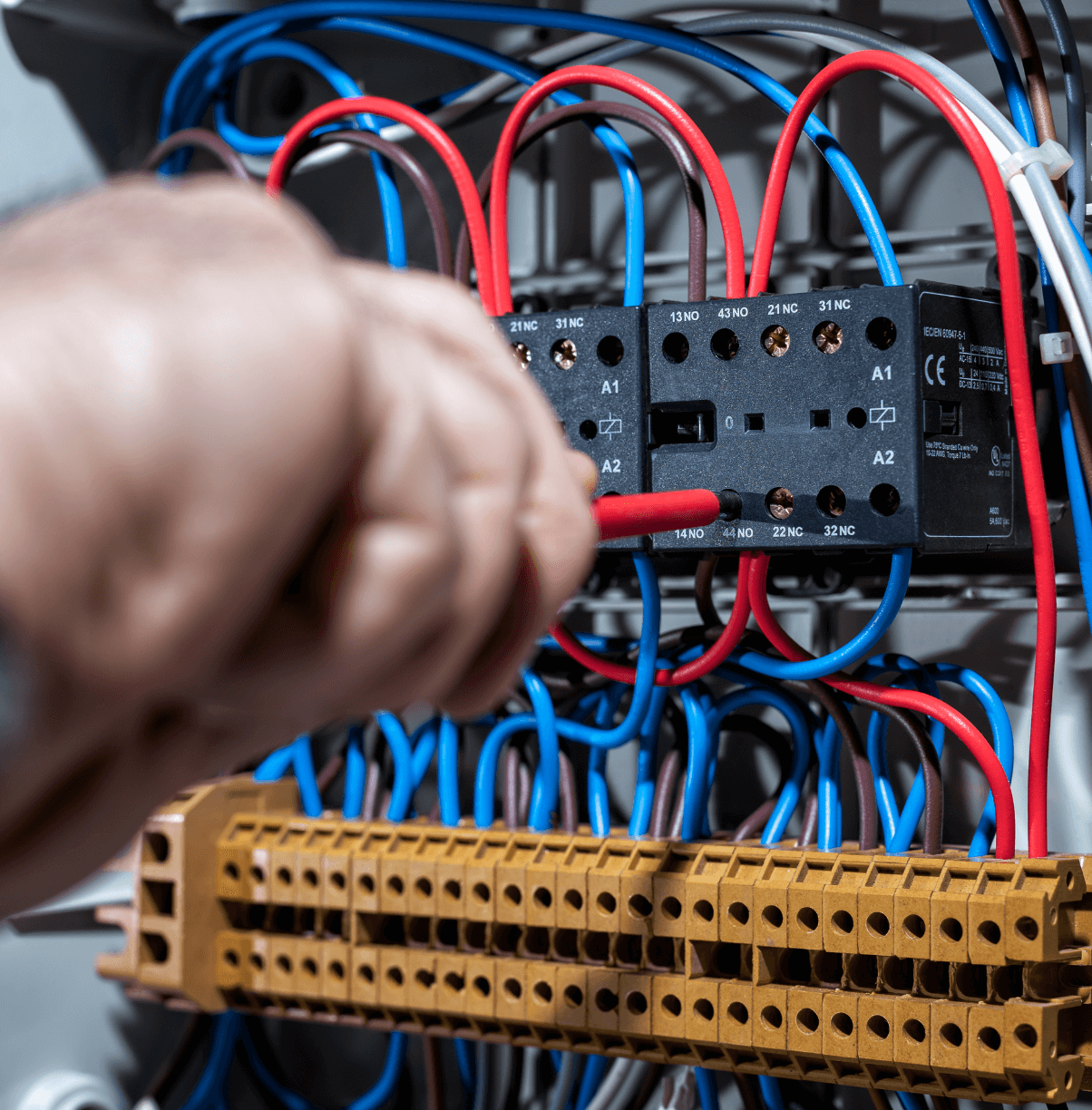

In 2002, Duplico created the first gas distribution odorization automation system.

Odorization of gas is carried out because gas is naturally colorless, tasteless, and odorless, and as such it is necessary to deodorize it before using it in households, i.e. give it an odor component - add an intense and unpleasant smell.

Method of polymetric transmission

Applying our method of polymetric transfer of static IP address back in 2002, we created the first gas odorization station automation system.

This is an exceptional requirement of the technological process due to the possibility of explosion, ignition, and environmental pollution. It is necessary to ensure redundancy and to ensure against each spark, which is a required process from the point of view of the profession.

Duplico has independently developed a remote control and monitoring system for odorizing gas stations, a telemetry device for remote reading of gas correctors - DuCom 2006, which is also the first Croatian device for remote reading of correctors that has been successfully implemented and tested in many utility companies throughout Croatia.

An app was developed for creating a nomination of natural gas consumption based on artificial neural networks.

'Machine to environment'

Duplico d.o.o. registered the trademark M2e ("Machine to environment") with the Croatian Intellectual Property Office in 2010, which refers to the creation of applications and hardware for systems that increase energy efficiency.

The trademark is registered, among other things, for devices for remote reading of electricity, gas, water consumption, computer applications for managing devices for the purpose of reducing energy consumption, and forecasting energy consumption taking into account meteorological and climatic conditions.

In cooperation with the Faculty of Electrical Engineering and Computer Science, we created the first nominator of gas consumption based on which, based on a mathematical model of time consumption, we created a forecast of gas consumption in a certain distribution area.

The request and challenge were prompted by penalties from the aspect of incorrect gas nomination due to transportation costs, and there is a certain possibility that the same thing will happen again in the future.

Based on Fuzzy Logic and Matlab, using special prediction tools with the help of professors from FER, we created such a model and managed to achieve an accuracy of 5 per thousand.

Through this application, we enable constant monitoring, collection, and display of various data on part of the reduction and odorization stations, as well as remote control of valves at certain points of the system, and that very easily - via the GPRS network.

SCADA in gas supply

In gas supply, SCADA has found wide applications. We built a SCADA based on Wincc software that displayed gas consumption results based on measurements at odorization stations and predicted their consumption 24 hours in advance.

In addition, we are an authorized dealer and representative of Lufkin - a system for vertical pumping, and vertical pumping of oil on wells of less yield. We applied and drilled 10 such wells at INA, which increased the total consumption and reduced operating costs.