What are control electrical cabinets?

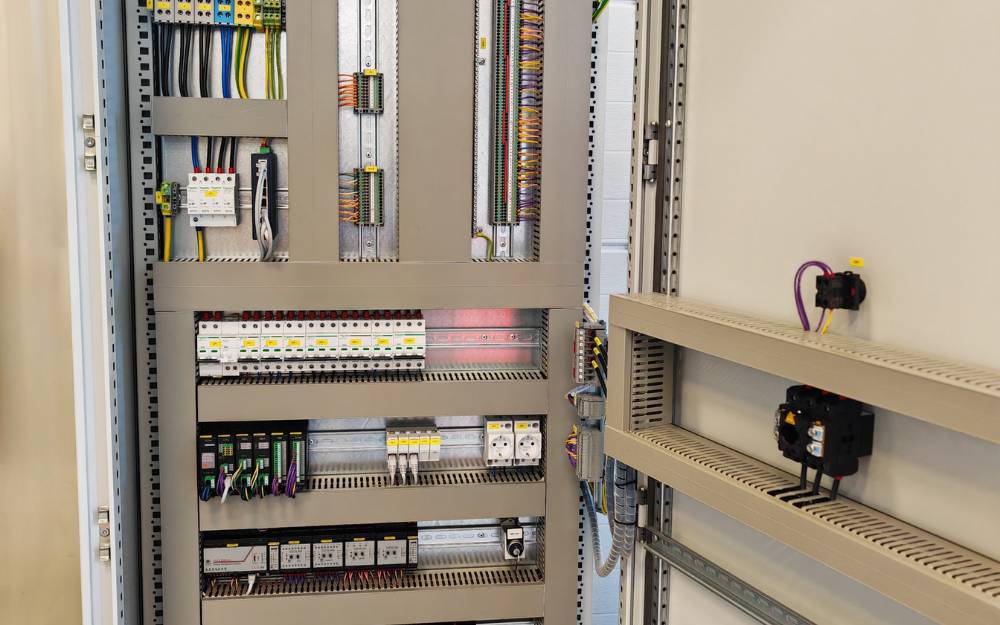

Control electrical cabinets are used for housing electrical components and equipment to facilitate the management and control of industrial processes, systems, and installations.

Furthermore, control electrical cabinets are employed for the organization, protection, and management of electrical components and equipment in various industries and systems.

The primary purpose of these cabinets is to enable system control and automation.

They are designed to organize, safeguard, and provide easy accessibility to various electrical components such as switches, relays, switches, converters, regulators, and other equipment necessary for automation and control.

Control electrical cabinets are constructed to shield electric components from external conditions such as dust, moisture, chemicals, or physical impacts, while also enabling the organization of different components in a manner that facilitates maintenance, diagnostics, and repairs.

Control electrical cabinets can be tailored specifically for certain industrial processes or standardized units.

Utilization of control electrical cabinets

Control electrical cabinets play a crucial role in the automation and management of various systems, including production lines, machinery, ventilation and air conditioning systems, transportation systems, energy distribution systems, and many other industrial and commercial applications.

The purpose of these electrical cabinets lies in their critical role in organizing, protecting, and managing electrical components and equipment within different industrial and technological systems. Moreover, they allow for precise coordination, automation, and supervision of various processes, providing reliable control points for the operation of machines, devices, and systems.

Their purpose is to achieve operational optimization, enhance energy efficiency, ensure and facilitate maintenance, contribute to increased productivity, reduced human intervention, and achieve stable and reliable operations within different industrial, commercial, and infrastructure environments.

The purpose of control electrical cabinets:

- energy control

- ensuring optimal energy usage, reducing costs

- preserving electrical components from external damages to maintain reliable operation

- coordination and supervision of different parts of the system, enhancing their cohesion and performance

Energy efficiency and control electrical cabinets

Control electrical cabinets are crucial for achieving energy efficiency in various systems.

Through automation, workflow optimization, energy consumption monitoring and analysis, and integration of renewable energy sources, they enable better resource utilization.

Moreover, control electrical cabinets efficiently manage peak loads, minimizing costs and strain on the grid. Furthermore they play a key role in enhancing energy efficiency, reducing energy consumption, and optimizing the operation of various systems.

Application of control cabinets in industry

Control cabinets are essential for a wide range of industries and systems. In production, they enable precise automation and coordination of machines, significantly increasing productivity. In energy plants, these cabinets ensure optimal utilization of energy, thereby reducing costs and increasing efficiency.

In construction projects, they precisely manage systems such as ventilation, lighting and security. Transportation systems rely on them to precisely control moving parts and ensure passenger safety. Furthermore, in water and utility systems, they ensure efficient operation of pumps and valves.

The versatile application of these cabinets is essential for optimizing performance, energy efficiency and overall functionality of various systems.

Duplico MOD Center

Duplico's expertise lies in complex control systems and electrical cabinets. We possess resources for assembling individual units, as well as small and medium-sized series of electrical cabinets tailored to specific customer requirements.

The development of Duplico electrical cabinets adheres to all electrical and functional safety regulations, as well as electromagnetic compatibility (EMC).

Our offering encompasses electrical cabinets with CE marking for the European market, as well as cabinets with UL certification for North American regions.

The automated production process of electrical cabinets

For designing and creating electrical cabinet schematics, we employ EPLAN.

Software tools like EPLAN facilitate the visualization of intricate systems, aiding in understanding functionality to avoid errors in production and rewiring.

This tool enables the creation of detailed schematics with additional information about routing and dimensioning.

Information is transferred to the "cloud" and transmitted to our production facilities, where machines such as cable and wire cutting and printing devices, CNC machines, and various equipment labeling printers are utilized. These machines employ the same data for further steps in the production process.

Thanks to this digital connectivity and integration of key elements and project stakeholders, we have complete data control, expedite the entire process, reduce human errors, and ensure cost-effectiveness.

3D modeling of control electrical cabinets

By successfully integrating advanced technology with our own software solutions, we have reshaped the electrical cabinet production process into an optimized and systematic flow that ensures fast production and exceptional quality control.

At the forefront of this process is precise 3D modeling using SolidWorks tools, which enables realistic visualization and significantly reduces possible errors during the design and assembly phase.

In addition, this tool accurately recreates each component within a three-dimensional environment, adhering to dimensions and specifications.

A commitment to high standards ensures that every electrical cabinet is thoroughly engineered, manufactured and delivered with unparalleled precision, strictly to predetermined specifications.

In addition, the production includes different variants of low-voltage electrical cabinets, all carefully tested according to the strict EN 61439 standard.