Energy sustainability in pharma manufacturing is a topic that has garnered significant attention in recent years. With the growing demand for pharmaceutical products and the increasing demand for environmentally friendly manufacturing processes, the need for sustainable energy practices in the pharmaceutical industry is crucial.

The pharmaceutical industry has traditionally been known for its high energy consumption and dependence on non-renewable resources.

With new technologies and the increasing awareness of sustainable energy practices, pharmaceutical companies are exploring various methods of reducing energy consumption and promoting energy sustainability in their manufacturing processes.

Energy cost savings in the pharma industry

One of the key drivers of energy sustainability in the pharmaceutical industry is the need for cost savings. This is particularly important in industries where costs are already high due to the need for extensive research and development, as well as the use of high-quality raw materials and advanced manufacturing processes.

In addition to cost savings, energy sustainability in pharmaceutical manufacturing also helps to reduce the carbon footprint. This is essential in a world where concerns over global warming and the depletion of natural resources are growing. By reducing energy consumption and promoting the use of renewable energy sources, pharmaceutical companies can help to mitigate the impact of their operations on the environment.

There are several approaches that pharmaceutical companies can take to promote energy sustainability in their manufacturing processes. One of the most effective methods is to invest in energy-efficient technologies, such as LED lighting, energy-efficient HVAC systems, and renewable energy sources such as solar and wind power. Another approach is to conduct energy audits to identify areas where energy consumption can be reduced and implement energy-saving measures accordingly.

Energy sustainability in pharmaceutical manufacturing is not only a critical issue for the environment, but it is also a business imperative for pharmaceutical companies. By reducing energy consumption and promoting the use of sustainable energy practices, companies can save costs, reduce their carbon footprint, and contribute to a more sustainable future.

Key trends for energy consumption in pharmaceuticals

The pharmaceutical industry is transforming in terms of energy consumption, with several key technological trends emerging.

- Renewable energy sources: The use of renewable energy sources, such as solar and wind power, is becoming increasingly popular in the pharmaceutical industry. By investing in renewable energy sources, companies can reduce their dependence on non-renewable energy sources and reduce their carbon footprint.

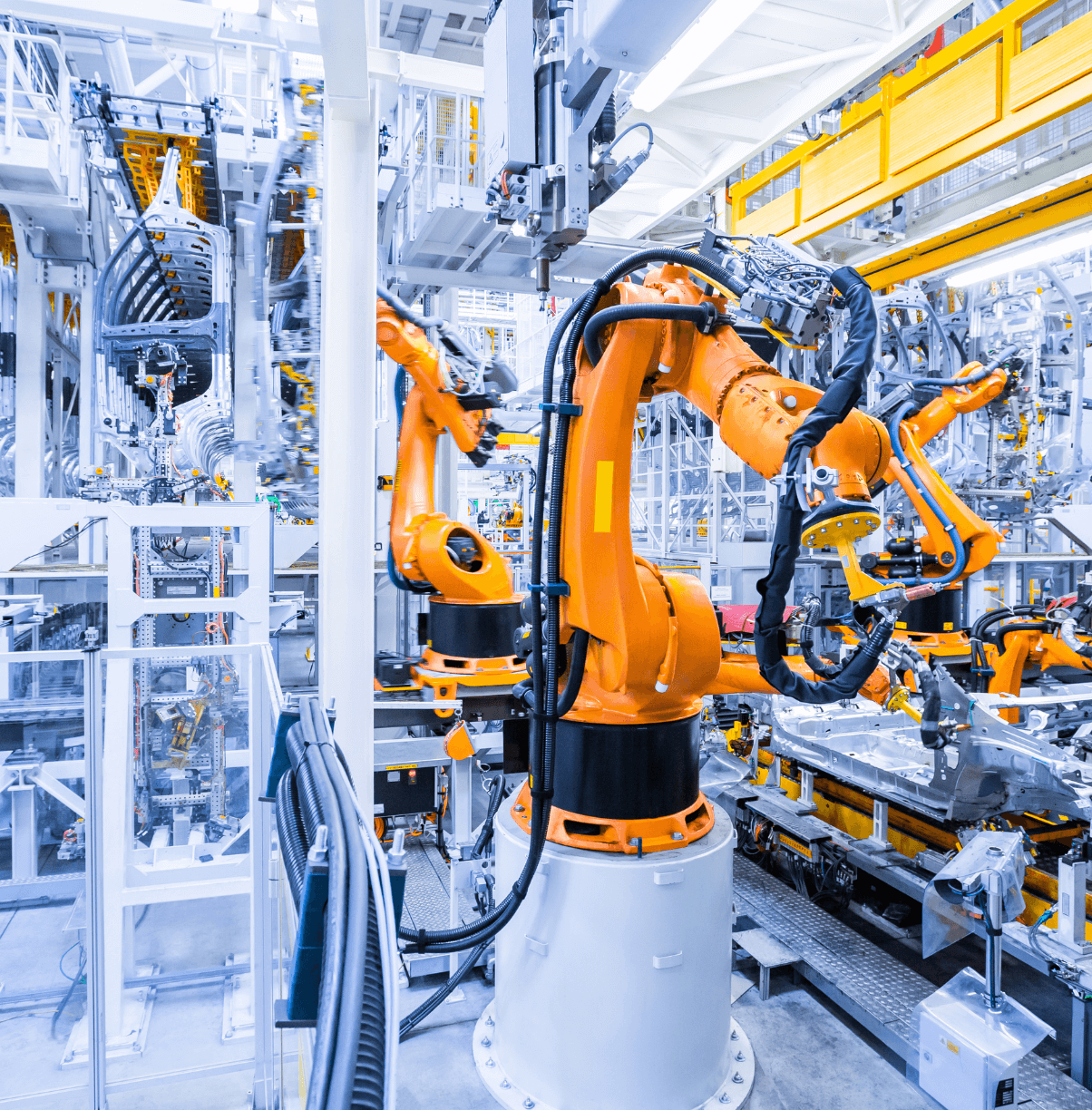

- Energy-efficient technologies: The use of energy-efficient technologies, such as LED lighting, energy-efficient HVAC systems, and energy-efficient manufacturing equipment, is also becoming increasingly popular. These technologies can significantly reduce energy consumption and help companies to achieve energy sustainability in their operations.

- Automation and digitization: Automation and digitization are key trends in the pharmaceutical industry that are helping to reduce energy consumption. By automating processes and digitizing data, companies can reduce the need for manual labor and increase efficiency, leading to lower energy consumption.

- Process optimization: Pharmaceutical companies are also focusing on optimizing their manufacturing processes to reduce energy consumption. This involves using predictive analytics and process modeling tools to identify areas where energy consumption can be reduced, and making changes to the manufacturing process accordingly.

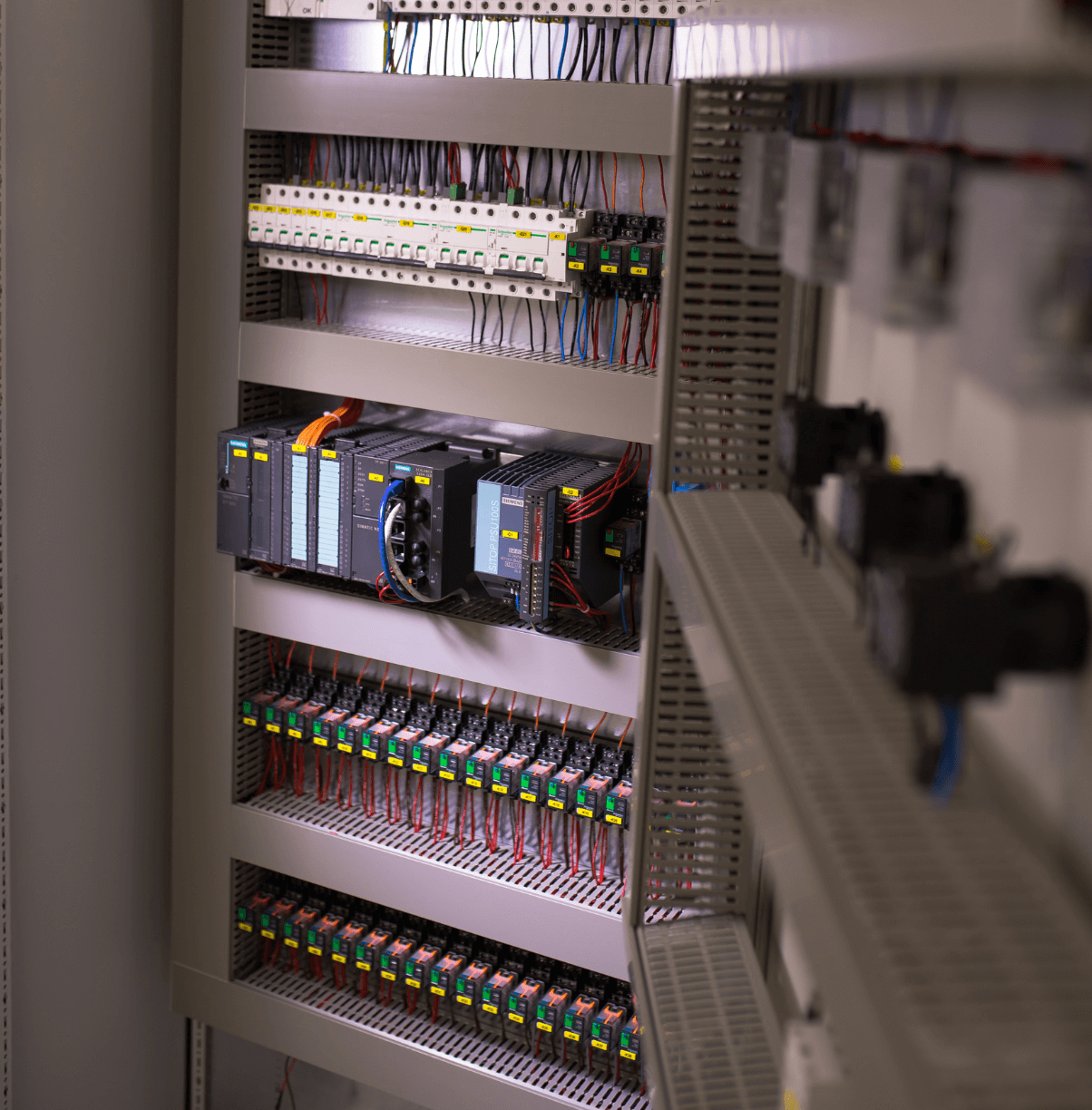

- Smart energy management: The use of smart energy management systems is becoming increasingly popular in the pharmaceutical industry. These systems allow companies to monitor and manage energy consumption in real time and make adjustments to reduce energy consumption and improve energy efficiency.

By embracing these trends, pharmaceutical companies can reduce energy consumption, save costs, and contribute to a more sustainable future.

Duplico energy solutions

Duplico is specialized in performing technical and non-technological installations in the pharma industry. Designing and executing piping, gas, and MUR heating technology, ventilation, air conditioning automation, and clean room management solutions for power generation, distribution, and energy consumption monitoring.

Duplico provides solutions for energy management, gas distribution, water supply, drainage, and remote monitoring through technological solutions.