A detail that will probably catch the attention of all those who visit our headquarters is that the walls are decorated with multiple lines branded with our colors.

The information that not so many are familiar with is that the lines are not solely a design element, but that they represent the backstory and a reminder of an idea that is as old as Duplico.

It is an idea of a robotic production of electrical cabinets that have been woven into our visual identity since the very foundation of the company. As a reminder of the technology we will be getting a grip on when the time comes.

Victor Hugo, a famous French poet, and novelist were credited with the phrase: „Nothing is more powerful than an idea whose time has come.“

The time was perfect for us to present a completely new technology.

We joined forces with our partner - the Faculty of Electrical Engineering and Computing (FER), and presented the project "Development of technology for connecting components of control electrical cabinets using laminated conductors" to our numerous partners and clients.

The DxL time is now?

As a company with decades of experience in the energy sector, we have established ourselves as one of the leading companies for designing and manufacturing complex technological systems, subsequently gaining valuable industry insights and comprehensive experience.

Throughout the years, the rapid development of digitization and robotization in production facilities increased the need for complex electrical installations in production systems.

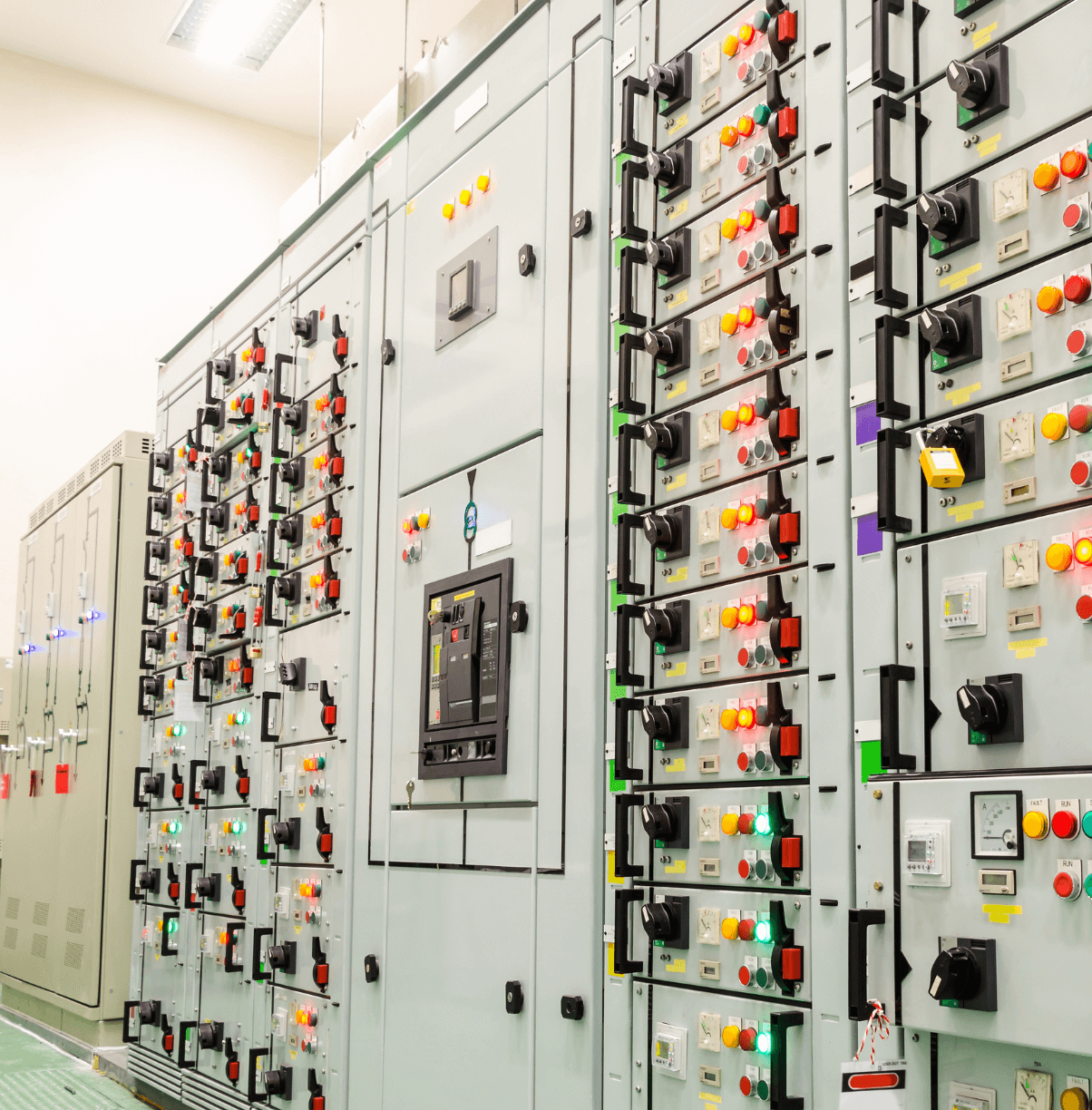

Electrical control cabinets are an important component in the energy network system within production systems, processes, or facilities that use large amounts of electricity

The complexity of manufacturing control cabinets depends on the organization of the network and the need for energy and is still completely done on a custom project basis.

The current organization and function of management and control electrical cabinets have not been significantly improved, therefore the need for more sophisticated and efficient technology became increasingly accentuated.

We named the technology DxL.

The first presentation of the DxL project

At a conference we presented the public with the vision, goals, and the future impact DxL technology will have on the approach to electric cabinet production, as well as an important role our partner - the Faculty of Electrical Engineering and Computing (FER), had in this project.

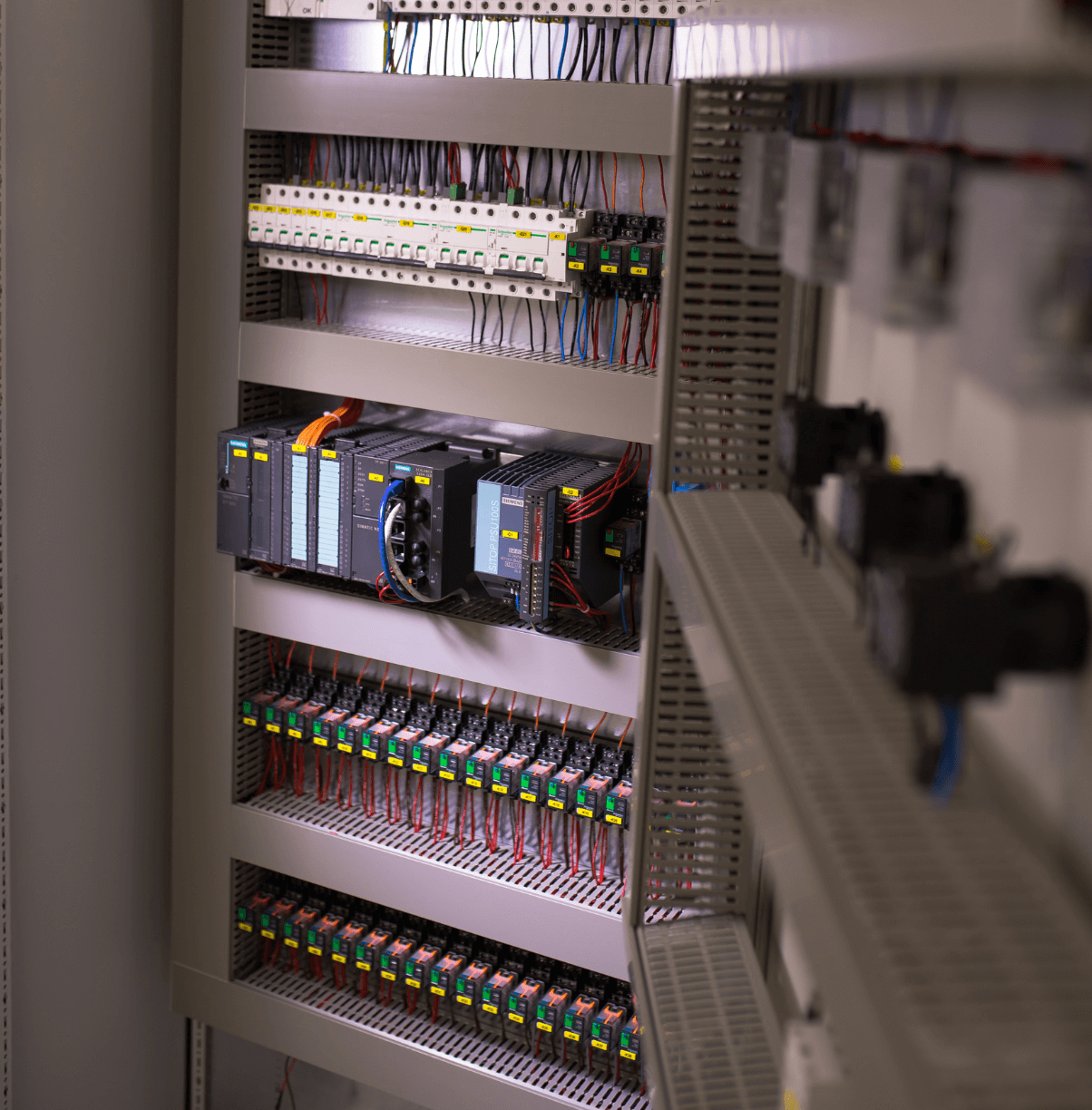

All the technological possibilities for connecting the components of the electrical cabinet through conductive and insulated connections that had been explored throughout the project were also shown.

The final result is a shortened wiring process between components and their simplified connections.

Electrical cabinets produced by utilizing this technology will be more simple, transparent, and energy efficient.

Material consumption will be significantly reduced, and the project will also have an indirect impact on ecology.

This will also create the basis for the first automated production of advanced electrical cabinets.

The application of new technology for complex electrical system design will enable high-quality monitoring and replacement of electrical cabinet components.

Consequently, each electrical cabinet will be produced in a significantly smaller dimension.

The project is implemented within the framework of the Call "Increasing the development of new products and services resulting from research and development activities (IRI)" - phase II, and co-financed from the European Regional Development Fund as part of the Operational Program Competitiveness and Cohesion 2014-2020.

In 2023. we will be eager to present the completed development of the technology, that had been already recognized by our strategic partners, and – to start a new era of the electric cabinet production process.